It also helps improve quality! We have established a consistent production system that carries out post-processing after casting.

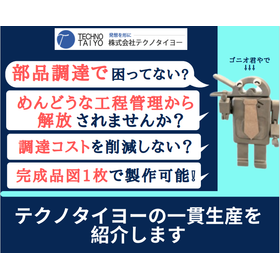

Our company has established a consistent production system that handles various shapes of castings (FC/FCD), die-casting, gravity casting, and other materials received from casting manufacturers, using new machine tools for the processes following casting. In response to the requests of major client manufacturers, we are able to provide finished products to large manufacturers. Additionally, before customer shipments, each manufacturing representative can hold meetings promptly, allowing for immediate understanding and correction of the workflow, issues, and areas for improvement, which contributes to quality enhancement. 【Features】 ■ Establishment of a consistent production system for processes following casting ■ Ability to provide finished products to large manufacturers ■ Each manufacturing representative can hold meetings promptly before customer shipments ■ Immediate understanding and correction of workflow, issues, and areas for improvement ■ Contributes to quality enhancement *For more details, please refer to the PDF materials or feel free to contact us.

Inquire About This Product

basic information

【Flow of Subsequent Processes】 ■ Cutting Process (Machining) ↓ ■ Assembly Process such as Press-fitting Bush Components ↓ ■ Pre-shipment Inspection ↓ ■ Packaging in Dedicated Boxes ↓ ■ Delivery *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(5)

Download All CatalogsCompany information

In 1969, our company, Tohshin Industries, started primarily with lathe processing. Since then, we have consistently and sensitively captured the trends of the times, actively introducing NC lathes, machining centers, multi-tasking machines, and robots. Currently, we operate over 50 machines day and night, producing a variety of processed products such as powertrain-related components for agricultural machinery and components related to industrial robots for major manufacturers. To overcome the challenging times ahead, our company will remain committed to the fundamentals of quality focus, cost reduction, and adherence to delivery schedules, engaging in management that is faithful to these principles. Furthermore, achieving these goals requires talented personnel. We will cultivate our workforce so that each employee develops an interest in processing technology, hones their skills and knowledge, engages independently in new processing endeavors, and aspires to be a skilled group that continuously progresses with a positive outlook. To continue living and developing alongside the times, we will strive for even higher quality and goals, and we kindly ask for your continued support.

![Integrated production service [*from mold design to mass production available*]](https://image.mono.ipros.com/public/product/image/62f/2000396395/IPROS8994794814776859441.png?w=280&h=280)

![Micron-level precision, high difficulty × short delivery time! Precision cutting processing [Processing case examples available].](https://image.mono.ipros.com/public/product/image/2070746/IPROS9035842601074547405.png?w=280&h=280)