We will realize the sub-assembly in your assembly line with our in-mold assembly!

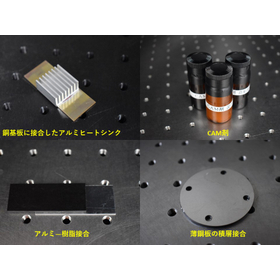

Examples of magnetic characteristic components for small motors / dissimilar material joining components (with photos) - Achieved high precision in positional accuracy between components - Elimination of Sub-Assembly on the assembly line - Reduced the main "5 processes" to the main "2 processes" Material: Magnetic SUS material, Non-magnetic SUS material Thickness: 0.2mm Application: Used in small components for mobile devices, mobile phones, etc.

Inquire About This Product

basic information

In the precision parts business of Misuzu Industries, we utilize the technology of press processing (metal and non-metal) for ultra-small and thin parts, developed through the manufacturing of watch components, to perform fine and complex shape cutting, bending, and drawing processes that were previously considered impossible with conventional pressing. Our integrated manufacturing system, from mold design and production to press processing and surface treatment, enables us to achieve micron-level shapes and precision as requested by customers, thereby meeting diverse needs.

Price information

For more details, please contact us.

Delivery Time

Applications/Examples of results

Mobile, mobile phone parts

catalog(1)

Download All CatalogsCompany information

In the precision parts business, we have achieved the processing technology for ultra-small and thin parts through press processing (metal and non-metal) developed in the manufacturing of watch components, along with a consistent in-house manufacturing system that encompasses mold design and production, press processing, and surface treatment. This allows us to realize fine and complex shapes that were previously considered impossible with conventional pressing, including cutting, bending, and drawing techniques. We shape micron-order geometries and precision while responding to our customers' diverse needs. In the precision assembly business, we leverage our long-standing high-precision and high-density bare chip mounting technology, primarily focusing on reel-to-reel FPC mounting, enabling us to provide consistent support from dicing to final testing and sub-assembly.