PSE Digital Twin Solution *A must-see for those concerned about DX!

gOES(gPROMS Operational Excellence Solutions)

For those who are worried about being assigned to the DX department... Leave it to us, with a proven track record of 2-10% energy cost reduction and payback in less than 9 months.

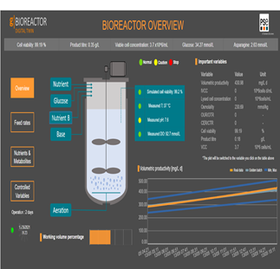

"Digital Transformation (DX)" has become mainstream, and more companies are establishing "DX departments." How about you? DX is not just about introducing technology; it requires a reevaluation of management policies, business models, and even organizational structures. Therefore, it is essential to promote a DX that suits your company rather than just a temporary fix. Our company offers 'gOES,' which digitizes processes in chemical manufacturing, pharmaceutical manufacturing, and food manufacturing, allowing for simulations. Based on data measured by sensors connected to products and factory equipment, we create a "digital twin" that enables customers to monitor the health and performance of their production processes in real-time. This contributes to efforts aimed at optimizing operating conditions. Among our lineup, 'gUTILITIES' is software for utility optimization. We have achieved energy cost reductions of 2-10% and a payback period of less than 9 months. *For more details, please refer to the materials or feel free to contact us.*

Inquire About This Product

basic information

【Lineup】 ■gOLEFINS: Software for accurate measurement prediction and monitoring of ethylene cracking furnaces ■gUTILITIES: Software for utility optimization ■gOILFIELD: Operational optimization of crude oil production systems ■gREFINERY: Operational monitoring of oil refining plants ■gREACTOR: Catalyst reactor model *For more details, please refer to the PDF materials or feel free to contact us.

Price information

Please consult us about the projects you are considering. We will provide a quote.

Delivery Time

Applications/Examples of results

[Results] <Effects of Introducing Our Products> ■gOLEFINS: Even just in terms of ethylene yield, large-scale plants see revenue improvements of $1 million to $3 million per month. ■gUTILITIES: 2-10% reduction in energy costs, with a payback period of less than 9 months. *For more details, please refer to the PDF document or feel free to contact us.

catalog(7)

Download All CatalogsCompany information

Founded in 1997 by the gPROMS development team at Imperial College London, PSE became part of the Siemens Group in 2019 and has been providing products and services in Japan as Siemens Corporation since 2023. gPROMS features a powerful equation-based computation engine that differs from traditional simulators, allowing for seamless handling of both steady-state and dynamic simulations. This enables the effective scaling up of models adjusted with experimental data from batch processing for the design and operational optimization of continuous processing plants. With gPROMS's excellent capabilities in custom modeling, parameter estimation, and optimization, it is possible to quickly build optimal manufacturing processes, resolve issues, and achieve optimization.

![[Example] AI Predictive Analysis and AI High-Speed Analysis 'AICFD'](https://image.mono.ipros.com/public/product/image/6da/2001510206/IPROS12220197373298392032.PNG?w=280&h=280)

![Understand in 3 minutes! What you can do with a manufacturing simulator [Materials Provided]](https://image.mono.ipros.com/public/product/image/10f/2001482625/IPROS15916837536830497441.jpg?w=280&h=280)