We respond to the need to minimize the variability in resistance values specific to contact probes as much as possible.

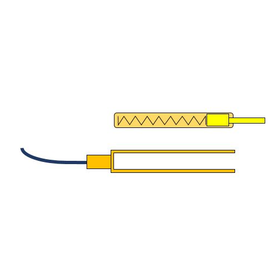

By using a bias structure and inserting a ball, we were able to increase the contact pressure on the inner wall of the pipe; however, this also resulted in significant damage to the inner wall, leading to issues such as probe sticking when used repeatedly. To address these disadvantages, Seiken combined parts using precision machining technology instead of balls, thereby reducing damage to the inner wall of the pipe while maintaining the characteristics obtained through bias. Furthermore, by miniaturizing the parts, we can also create a bias structure compatible with P=0.4mm. We respond to the need to minimize variations in resistance values specific to contact probes, such as in low-resistance measurements. *For more details, please refer to the PDF document or feel free to contact us.*

Inquire About This Product

basic information

【Features】 - Components are combined using precision machining technology instead of balls. - Reduces damage to the inner wall of the pipe while maintaining the characteristics obtained from bias. - By miniaturizing the components, it is possible to create a bias structure compatible with P=0.4mm. - Responds to the need to minimize variations in resistance values specific to contact probes. *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(2)

Download All CatalogsCompany information

Our company is a manufacturer that has developed and designed inspection equipment essential for quality assurance. Since our founding in 1984, we have started manufacturing and selling various inspection jigs, specializing in probe pins and their application products. Since then, we have responded to customer needs in various markets, including semiconductor component inspection jigs such as probe cards and IC sockets, as well as liquid crystal panel inspection jigs. As a leading company in the industry, we have refined and honed our precision processing and assembly technology over many years. Keeping pace with the changing times, as a "TOTAL TEST SOLUTION" provider, we will continue to tackle the challenges in inspection operations with various products and services as a good partner for our customers. In recent years, we have also been providing the technology and know-how we have accumulated in producing our products to our customers through our EMS business. In addition to our unique skills, we also offer various support in manufacturing by matching our customers with partner companies and related firms. Seiken will always challenge itself, create new value, and pave the way for the future of manufacturing in Japan.

![Semiconductor Testing [Contact Probes, IC Sockets, Probe Cards]](https://image.mono.ipros.com/public/product/image/6d6/2000410005/IPROS91145408194563330894.jpeg?w=280&h=280)

![[Example] Contact at narrow pitch and multiple points with a stacked probe.](https://image.mono.ipros.com/public/product/image/772/2000444738/IPROS49194200914327221558.png?w=280&h=280)

![[Example] Stable contact of the stacked probe](https://image.mono.ipros.com/public/product/image/81f/2000444735/IPROS30920659778591143416.png?w=280&h=280)