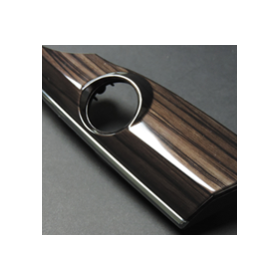

Thin-walled molding technology that greatly contributes to the miniaturization and slimness of products.

The lightweight and slim design of wearable devices is greatly contributed by the lightweight and slim plastic components. At Life Mold, we have been working on this thin-wall molding technology for many years, starting with a thickness of less than 0.6mm in 1998, and we have now achieved ultra-thin wall molding with a thickness of 0.2mm.

Inquire About This Product

basic information

**Features** Thin-walled molding requires the "fusion of technologies" in design, mold, and molding. - To perform thin-walled molding, high-rigidity and good gas venting mold design technology is essential. - Precision technology for manufacturing molds for thin-walled applications. - Skilled techniques to accurately control the speed, pressure, and temperature of the injection molding machine. A balanced integration of all these elements is necessary. Our unique technology, which can be realized because we provide a comprehensive environment from mold design to injection molding, sets us apart.

Price range

Delivery Time

Applications/Examples of results

■Small battery case ■Wearable device

catalog(1)

Download All CatalogsCompany information

Life Mold Co., Ltd. provides high-quality plastic molded products, including in-mold decoration (IMD molding) and insert molding (IML molding). Additionally, we handle a wide range of technologies, including thin-wall molding technology that significantly contributes to the miniaturization and thinness of products, as well as exterior parts and mold processing. Please feel free to contact us first.

![[Technology] Adjustment of ultra-small precision parts and ultra-thin wall molding](https://image.mono.ipros.com/public/product/image/7c2/2000857755/IPROS89493922422903483871.png?w=280&h=280)