Supports resin-based coatings that can be film-coated, as well as vacuum-deposited films like DLC!

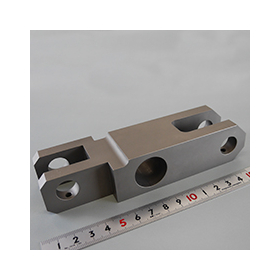

No matter how much metal is polished, there are limits to performance in sliding environments, and wear is an unavoidable issue when using sliding components. By applying lubricating and wear-resistant coatings to these sliding components to improve sliding characteristics, as well as load-bearing coatings to parts used in harsh environments, it is possible to enhance product functionality. At Sawahira, we can accommodate resin-based coatings that can be applied with general spray coating, as well as vacuum deposition films like DLC. 【Features】 ■ Coating applied to areas with high friction and wear on sliding parts ■ Functions such as oil-free and grease-free are provided ■ Fluororesin (Teflon) is used as a general lubricating coating ■ For use in high load areas, materials such as molybdenum disulfide and PEEK resin are used *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Lubricating and Load-Bearing Coating Types】 ■ Fluororesin ■ PEEK Resin ■ Molybdenum Disulfide *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Examples of Application】 ■Industrial Equipment: Shafts, gears, oil-free sliding parts (bearings, spools, etc.) ■Medical Equipment: Tweezers, guide wires, surgical needles, general sliding parts, springs ■Automotive Equipment: General sliding shafts, valve lifters, piston skirts, washers, compressors, gear components *For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Sawaheira Co., Ltd. has been building deep trust with everyone since its establishment in 1959 as a company capable of consistently handling everything from machining and pressing of machine parts to various coatings and assembly work. Our company contributes to cost reduction by being able to manufacture machine parts consistently, and we have also strived to be of service to everyone with our advanced technology and reliable quality control in cutting-edge precision machining, metal processing technology, and functional coating technologies such as fluororesin and molybdenum disulfide. Moving forward, we are committed to further advancing "technology development" and "quality control" to meet our customers' needs.

![[Research Material] Global Market for Inorganic Waterproof Coatings](https://image.mono.ipros.com/public/product/image/8a6/2001474238/IPROS49868365252821124262.jpeg?w=280&h=280)

![[Example] Preventing metal migration due to moisture in multilayer printed circuit boards.](https://image.mono.ipros.com/public/product/image/984/2000640006/IPROS21370121225881087240.jpeg?w=280&h=280)

![[Example] Using FluoroSurf as a concentrated waterproof spray.](https://image.mono.ipros.com/public/product/image/84e/2000640116/IPROS83989113576455681480.jpeg?w=280&h=280)