Addressing static electricity issues with substrate placement jigs! Jigs that protect semiconductors and other components from damage due to static electricity can be produced in-house at low cost and with short lead times!

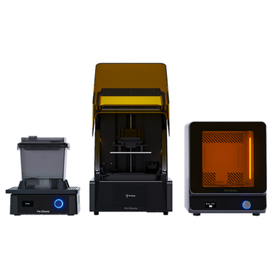

What is required of jigs and trays for electronic components, in addition to being non-static, is to have a moderate softness to avoid damaging delicate parts. ■ Features of the printer <Stable molding with unique mechanisms> 〇 Heat bed to prevent model warping 〇 Cooling fan to suppress resin drooping 〇 Auto-leveling function that maintains a constant distance between the nozzle and the table (excluding Bellulo200) 〇 Table drive to prevent shaking and tilting 〇 Easy and efficient material exchange - Equipped with parameters for conductive filament "NLU1618" - Capable of producing jigs using conductive filament - Achieves smooth surface quality with stable molding - Easy and smooth operation - Reliable support system even after installation * For more details, please refer to the product catalog. * For inquiries, please contact the Industrial Machinery Systems Division.

Inquire About This Product

basic information

<Conductive Filament> The developed conductive filament for 3D printers is a filament in which carbon nanotubes (CNT) are uniformly dispersed in an elastomer. By incorporating CNT, it forms a fine and dense conductive network within the material, preventing the accumulation of charge and resulting in a non-charged state. <Features of Conductive Filament> 〇 Low Surface Resistance Generally, materials like ABS and PLA used in 3D printers are insulators and tend to accumulate charge, but the conductive filament is controlled to have a surface resistance value of 10³ to 10⁶ Ω/sq, making it an excellent material for charge dissipation. 〇 Flexibility Not Found in Normal Materials In delicate substrate fixtures, if the material is too hard, it can break, and if it is too soft, it may not be stable; therefore, moderate flexibility is required. The conductive filament has rubber-like elasticity (Shore A hardness of 80 to 85 degrees), allowing for adequate friction and elasticity to work without damaging the substrate. <Three Features> - Excellent conductivity - No carbon shedding, clean - Flexibility not found in resins <Specifications of Conductive Filament> Filament Diameter: φ1.75mm Net Weight: 500g Filament Color: Black

Price range

Delivery Time

Applications/Examples of results

【Usage】 * 3D Printer * Conductive Special Filament <Three Features> - Excellent conductivity - Clean with no carbon shedding - Flexibility not found in resin <Specifications of Conductive Filament> Filament Diameter: φ1.75mm Net Weight: 500g Filament Color: Black

catalog(1)

Download All CatalogsNews about this product(2)

Company information

Taiyo TechnoRex Co., Ltd. continues to operate in the fields of prototype development of flexible printed circuit boards (FPC) and printed circuit board testing systems. Since FPC is fundamentally related to the structure of hardware, both high precision quality and shortened development time are required. We have extensive experience and know-how in the manufacturing processes of single-sided FPC, double-sided FPC, multilayer FPC, and their advanced types, and we continuously improve and enhance our technology, resulting in consistent evaluations of our delivery times and quality. Additionally, while technically advancing further miniaturization and high density, we are also undertaking new initiatives such as bump-type and special material electroplating. On the other hand, our printed circuit board testing systems mainly consist of electrical inspection systems and final appearance inspection systems, which are adopted in the mass production sites of FPCs and package/module-type substrates. They operate day and night in quality control settings for substrates used in smartphones, automotive applications, and various electronic devices. We will continue to respond to the increasingly diverse market needs. *On December 21, 2023, the company name was changed from "Taiyo Kogyo Co., Ltd." to "Taiyo TechnoRex Co., Ltd."*