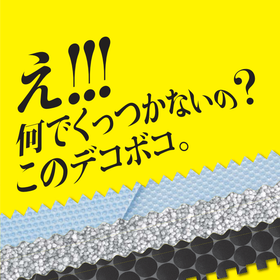

Surface treatment technology: "Non-stick and release properties created by unique convex surface treatment."

Our unique surface treatment technology enables the prevention of sticking for particularly sticky materials such as molten plastic, labels, adhesive tape, and raw rubber!

We have prepared a series that exhibits excellent non-stick and release properties, particularly against sticky materials such as adhesives, molten resins, and adhesive tapes. ■ Series Composition - Super TP/TP Series (all fluoropolymer) - Super CTT Series (surface treatment + siloxane) - Super Alloy Coating ■ Super TP/TP Series The entire surface treatment is composed of fluoropolymer, making it usable in silicone-free environments. Additionally, there is no siloxane contamination. ■ Super CTT Series Thanks to a special convex surface treatment and silicone rubber, it demonstrates outstanding non-stick properties. When using, consideration must be given to the potential transfer of silicone to the counterpart material. ■ Super Alloy Coating This release coating allows for surface adjustment using a special alloy that balances flexibility and high hardness. There are both fluorine-based and silicone-based series, and surface treatment with HV600 can be applied to resins and sponge rubber as well. *For more details, please click on "PDF Download" or feel free to contact us.

Inquire About This Product

Related Videos

basic information

Product Lineup of Each Series ■ Lineup of Super TP Coatings (Fluoropolymer-based) ● Super TP 250 UNDER ● Super TP 250 UP ● Super TP 500 UP ● Super TP Hemisphere Graphic HW ● Super TP Hemisphere Graphic HS ● Super TP Hemisphere Graphic HL ■ Lineup of Super CTT Coatings (Silicone-based) ● Super CTT N Type ● Super CTT T Type ■ Lineup of Super Alloy Coatings ● Plastic and Rubber Processing Series ・Silicone-based (Processing Temperature RT to 80℃) ・Fluoropolymer-based (Processing Temperature 130 to 180℃) ● Heat-resistant Substrate Processing Series ・Fluoropolymer-based (Processing Temperature 300 to 400℃) *For more details, please click on "PDF Download" or feel free to contact us.

Price information

-

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(3)

Download All Catalogs

News about this product(2)

Company information

To maximize the performance of manufacturing equipment and machine parts, Yoshida SKT derives the "optimal solution" tailored to our customers from hundreds of surface treatment technologies. - Decreased productivity due to adhesive troubles - Instability in product quality due to friction - Early deterioration of equipment due to corrosion We respond to these challenges in the manufacturing field with our extensive track record and reliable technical expertise. In 1963, we began fluoropolymer processing. In 1968, we signed a licensing agreement with DuPont (now Chemours), supporting manufacturing innovations for over 2,000 customers across various industries, from automotive to medical and aerospace. Furthermore, in 2024, we are focusing on the development of next-generation products, such as PFAS-free coatings, contributing to the advancement of sustainable manufacturing. With a three-base system in Nagoya, Tokyo, and Yamaguchi, we flexibly respond to both mass production and custom orders. Our consistent quality management system ensures that we deliver reliable quality. For solving challenges in the manufacturing field, trust the surface treatment experts at Yoshida SKT.

![Surface treatment technology [Elekote]](https://image.mono.ipros.com/public/product/image/770/2000128789/IPROS5056879095544230771.JPG?w=280&h=280)