Complete removal of plating from the top, bottom, and sides! There is no need for plating removal work before welding.

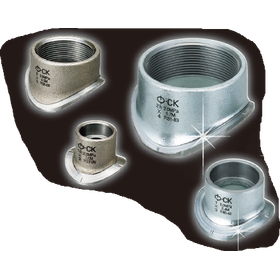

"Tsurupika-kun" is a welding saddle certified by the Japan Fire Equipment Safety Center. It allows for immediate and speedy welding. The zinc coating on the top, bottom, and sides of the saddle body, which is the welding area, has been completely removed. There is no longer a need for the cumbersome and time-consuming process of removing zinc with a grinder. This improves work efficiency and welding efficiency, allowing for cost reduction. 【Features】 ■ Immediate and speedy welding ■ Improved welding quality ■ Total cost reduction ■ Improved working environment *For more details, please refer to the PDF materials or feel free to contact us.

Inquire About This Product

basic information

【Other Features】 - Complete removal of plating from the top, bottom, and sides - No need for plating removal work before welding - Since the plating at the weld area is removed, there is no risk of harmful zinc gas generation - Improved work efficiency and welding efficiency, allowing for cost reduction - Minimal gas generation, with a worker-friendly saddle - The plating on the joint surface (white product) meets environmental standards, with cadmium less than 0.001% (10ppm) and lead less than 0.005% (50ppm), fully complying with the RoHS directive - Four "centering marks" are displayed on the joint body for positioning, which helps improve quality and work efficiency in construction *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

"Where it is said to be impossible, there lies the possibility." The fittings branded with the CK logo are filled with various trials and errors. For example, the development of new materials that are friendly to people and the Earth is one of them. In the "Piping Equipment Business" division, we have developed and commercialized fittings such as "PVC-free" and "lead-free," as well as the world's first "cadmium-free" fittings. Additionally, in the "Hot-Dip Galvanizing" division, we developed the world's only hot-dip galvanized coating, "CKe coating," which does not contain lead or cadmium, and it has also been registered in the Ministry of Land, Infrastructure, Transport and Tourism's new technology information provision system, "NETIS." We have successfully mass-produced the world's first RoHS-compliant fittings using this technology for surface coatings, continuously creating new products as a leading company in the industry. With unique technologies that are not found in other companies, we are bringing the world's first products to market. CK Metal's manufacturing spirit continues to pursue new possibilities with "environment" as its theme.