Uniformity in pressing force enables robotic polishing of stainless steel food machinery.

FerRobotics AOK

Automating the artisan's skills (polishing, grinding), heavy labor, and dangerous tasks with uniform control of contact force on the workpiece through a high-speed autonomous control system. Inspiring improvement levels.

FerRobotics' Active Compliant Technology automatically corrects the "difference" in contact pressure (force) that occurs during polishing and grinding processes, which require skilled techniques, at high speed. This technology allows for consistent polishing/grinding at the set contact force, unaffected by variations in processing speed or gravitational load differences due to angles. With the end effector (ACF) utilizing ACT technology, it instantly and automatically compensates for changes in dimensional tolerances, curved shapes, and non-flat surfaces by rapidly adjusting the stroke length, maintaining contact with the workpiece at the set force. This technology enables an increase in the speed of the equipment and the robot's trajectory, thereby enhancing processing speed and improving cycle times. In robotic polishing, the ACF's stroke adjustment controls the contact pressure, eliminating the need to move the heavy robot arm for corrections, which further assists in improving processing speed. Additionally, it automatically compensates for tool load variations caused by gravity changes due to the robot's angle, ensuring a consistent contact pressure from any angle and allowing for a finish without processing inconsistencies.

Inquire About This Product

basic information

Example usage videos are available on the official FerRovotics YouTube channel. Search for "FerRobotics"!! ◆Challenges addressed through automation of polishing and grinding using our technology - Reduction of labor costs and creation of profits through automation - Increased work speed and improved cycle time - Ability to reproduce high-quality finishes without individual variation - Mitigation of the risk of inheriting skilled worker issues - Relief from the "three K" jobs for workers - Consistent work with high reproducibility available 24/7, 365 days a year - Cost reduction possible by minimizing the consumption of consumables through consistent pressure during processing

Price information

Please contact us.

Delivery Time

Applications/Examples of results

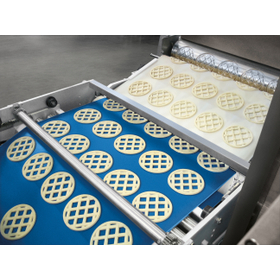

Automotive, aerospace, railway, sanitary products, grinding and polishing processes in steel mills (Example application videos available on the official YouTube channel. By FerRobotics.) Examples: Welding bead removal, welding spatter removal, sanding before painting, polishing turbine blades, sanding and polishing of sanitary and other ceramic products, deburring of cast parts, polishing wind turbine blades, polishing acrylic glass, and various types of buffing and mirror polishing. ◆ Polishing Processes - Grinding after laser brazing of the roof joints of automotive bodies - Removal of welding spatter, soot removal, sanding, and brushing at door entry points - Repair polishing - Sanding before painting - Polishing - Deburring and polishing of cast, metal, and plastic parts, etc.

Detailed information

-

Using our patented technology, Active Compliant Technology (ACT), we provide the best solutions for robotic polishing and robotic grinding, equipping industrial robots with tactile feedback and enabling greater flexibility, reliability, and profitability in manufacturing environments than ever before. The ACT, optimized for robots, automatically measures the required pressing force, instantly compensates for complex surface shapes, and allows for consistent processing with a fixed pressing force. It can also respond to sudden opposing forces, such as when the target workpiece moves. As a standard tool and as a custom package product tailored to special requirements, ACT clearly contributes to efficiency improvements in production processes that have previously been impossible to automate. By confirming the performance of our ACT solutions, you will immediately feel the results. It brings overwhelming effectiveness to automated polishing and grinding (including polishing, sanding, grinding, deburring, buffing, mirror finishing, etc.).

catalog(1)

Download All CatalogsNews about this product(3)

Company information

FerRobotics Compliant Robot Technology is a technology development company based in Austria. As a global leader in the development and sales of units that give robots flexibility and sensory capabilities, we provide our customers and business partners around the world with the highest quality experiences and have earned their strong trust. Our patented Active Compliant Technology (ACT) can give robots a "perfect sense," making it applicable to most surface processing tasks and delicate handling operations that require precise contact. We offer solutions that enable the automation of tasks that have previously been impossible to automate in various industries, including automotive, aerospace, rail, and many others. We are a company that continually pursues and strives for "perfection" to deliver solutions that achieve the highest quality standards and improve reliability. Thanks to our experience and advanced expertise, we have gained high trust from users worldwide. We have many application example videos available on YouTube. We hope that by searching for FerRobotics, you can envision solutions to your company's challenges.

![[Robot Arm Load Capacity Compatible!] Robot Hand & End Effector](https://image.mono.ipros.com/public/product/image/ba7/2000443613/IPROS40389073862814140691.png?w=280&h=280)