What can high-precision hole machining actually do? We have summarized what we can handle based on our track record, including material, hole diameter size, depth, and precision!

At U Corporation, we achieve micron-order ultra-precision machining using our long-cultivated know-how and high-precision equipment environment for both resin and metal materials! Our company handles everything from research and development prototypes to small-lot manufacturing across a wide range of fields, including medical devices, aerospace, optics, electronics, and office automation. We produce high-precision, high-quality items daily, such as oxygen-free copper "acceleration tubes" and "thruster injectors" used in satellites. We have prepared materials that explain our high-precision hole machining in just three minutes! *For more details, please refer to the PDF document or feel free to contact us. ★Industries and Fields We Serve 〇 Aerospace 〇 Semiconductor and Electronic Equipment 〇 Medical Devices 〇 Cameras and Office Automation Equipment 〇 Automotive, etc. *We also accept commissioned measurements using CT scan measurement and other methods in-house. *For more details, please refer to the PDF document or feel free to contact us. When inquiring, please reach out via the related link (contact form) below.

Inquire About This Product

basic information

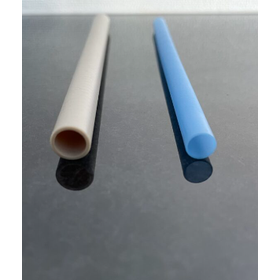

We handle a variety of resin machining such as ABS, PC, POM, acrylic, PP, PPS, and PEEK, as well as metal machining for aluminum, stainless steel, and difficult-to-machine materials like titanium, Inconel, Kovar, and Super Invar. If you are facing challenges with complex shapes, please feel free to consult with us! ★ Material and Material Examples ◾ Resins ⇒ ABS, POM, PC, PC-ABS, PMMA: acrylic, PPS, PP, PEEK, AES, PBT, PPE: Noryl, PTFE: Teflon, PA: nylon, PA6, PA66, Ultem, various rubbers, etc. ◾ Metals ⇒ Aluminum: A1050 to 7075/ADC12, Copper: oxygen-free copper/brass/phosphor bronze, carbon steel stainless: SUS303/304/420J2/430/440/630, steel materials, magnesium, titanium, Invar, Inconel, molybdenum, permalloy, nickel, tantalum, Kovar, tungsten, etc. * For more details, please refer to the PDF document or feel free to contact us.

Price information

The variation depends on the shape, material, size of the parts, and the desired dimensional accuracy. Please feel free to contact us for a quotation.

Delivery Time

※The delivery date may vary depending on the processing details, so please feel free to contact us.

Applications/Examples of results

★Service Examples ◎Processing ■ Resin cutting ■ Metal cutting ■ Difficult-to-cut material cutting ■ Brittle material processing ■ Micron order support ■ Quality assurance support ◎Measurement ○ Contract measurement ○ Internal observation ○ Internal analysis ○ Internal measurement ○ Reverse engineering ○ Measurement data provision ○ Measurement model provision ○ 3D model provision, etc. ★Certification Acquired ※ ISO 9001 acquired ※ JIS Q9100 acquired ※ Medical device manufacturing registration ★Industries and Fields Served 〇 Aerospace and space fields 〇 Semiconductor and electronic equipment fields 〇 Medical device fields 〇 Camera and office automation equipment fields 〇 Automotive fields, etc. ★Equipment Owned ◎Processing ・ 5-axis/3-axis machining centers ・ NC composite lathes ・ Wire electrical discharge machines ・ Die-sinking electrical discharge machines ・ Automatic surface grinders, etc. ◎Inspection ・ Measurement X-ray CT scan system: Shimadzu Corporation, XDimensus 300 ・ Contact-type three-dimensional measuring machines ・ Non-contact three-dimensional measuring machines ・ Roundness measuring machines ・ Ultra-depth shape measuring microscopes ・ Surface roughness measuring machines ・ Various gauges, etc. ※ For more details, please refer to the PDF materials or feel free to contact us.

catalog(16)

Download All Catalogs

News about this product(24)

Company information

Since our establishment, You Corporation has continued to strive for corporate efforts based on the management philosophy of self-transformation in line with the changes of the times. We have raised our antennas high to quickly read the changes in the era and have engaged in the battle of transforming ourselves by honing our sensitivity to information. Today, we believe that the significant support we receive from our customers in our three divisions—TEC, E&T, and APPA—reflects the appreciation for these efforts. Moving forward, we will aim to be a one-of-a-kind company with absolute competitiveness by continuously pursuing self-transformation ahead of others, without being bound by past successes.

![[Improvement Case] High-Precision Machining of Fine Holes](https://image.mono.ipros.com/public/catalog/image/01/85b/571352/IPROS36352143116935082139.jpeg?w=120&h=170)

![[Technology] Telescope Tube | Precision Machining | Inner and Outer Cam Processing](https://image.mono.ipros.com/public/catalog/image/01/85f/585707/IPROS68334803320050337100.jpeg?w=120&h=170)

![[Example] SUS304 Special Flange Processing (Without Gundrill)](https://image.mono.ipros.com/public/product/image/7f7/2000260568/IPROS4859060381787314981.jpg?w=280&h=280)

![[Processing Reference Example] Casing Screw Machining](https://image.mono.ipros.com/public/product/image/2088546/IPROS16021466541096188662.png?w=280&h=280)