Solve release agent issues with innovative silicone coating technology!

■What are the issues with release agents? Release agents are known to be applied in industrial fields to improve the separation of molded products from molds. In addition to facilitating mold release, release agents also need to have properties that make them resistant to degradation from heat during molding and minimize contamination of the mold. Silicone is often used as a release agent because it has high heat resistance, does not easily degrade with repeated heating during molding, has low surface tension which provides good wettability to the mold, and can reach every corner of the shape. While silicone release agents have excellent effects, they can also impose a burden on the working environment, increase the effort required for mold cleaning, and lead to variations in the amount applied by workers, which may negatively impact the final product. ■Silicone Coating Technology Silicone coating technology balances release properties and maintenance, leading to solutions for release agent issues. ▼For more details about the coating, please click the URL below or contact us.

Inquire About This Product

Related Videos

basic information

"MRS Coating" (Silicone Coating) [Introducing a part of our lineup] ■MRS-102 Maintains effectiveness even after cleaning with solvents. ■MRS-014 Preserves shapes such as thinness like a blade and textures. ■MRS-004 Heat resistance exceeding 200°C, comparable to fluororesin (Release even after 16 hours at 350°C). ■MRS-200 Can be processed at temperatures below 80°C for resin and rubber products. *For more details, please download the PDF or contact us.

Price range

Delivery Time

※It varies depending on the specifications. Please feel free to contact us.

Applications/Examples of results

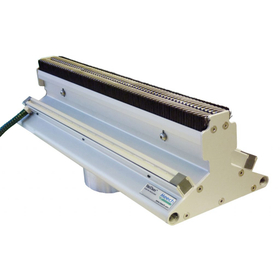

■Examples of Processing Applications <Coating Function> ◆Adhesive Paper Transport Roll - Prevents adhesive from sticking to the roll <Cleanability> <Release Property> <Smoothness> ◆Film Cutting Table - Prevents sticking to the support surface <Cleanability> <Release Property> <Smoothness> ◆Measuring Cup - Prevents adhesion (residue) of measured items <Cleanability> <Water Repellency> <Smoothness> ◆Sandwich Cutting Blade - Prevents sticking to the blade <Cleanability> <Release Property> <Thin Film>

catalog(1)

Download All CatalogsCompany information

To maximize the performance of manufacturing equipment and machine parts, Yoshida SKT derives the "optimal solution" tailored to our customers from hundreds of surface treatment technologies. - Decreased productivity due to adhesive troubles - Instability in product quality due to friction - Early deterioration of equipment due to corrosion We respond to these challenges in the manufacturing field with our extensive track record and reliable technical expertise. In 1963, we began fluoropolymer processing. In 1968, we signed a licensing agreement with DuPont (now Chemours), supporting manufacturing innovations for over 2,000 customers across various industries, from automotive to medical and aerospace. Furthermore, in 2024, we are focusing on the development of next-generation products, such as PFAS-free coatings, contributing to the advancement of sustainable manufacturing. With a three-base system in Nagoya, Tokyo, and Yamaguchi, we flexibly respond to both mass production and custom orders. Our consistent quality management system ensures that we deliver reliable quality. For solving challenges in the manufacturing field, trust the surface treatment experts at Yoshida SKT.