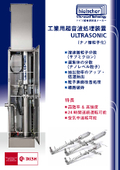

Carbon Ultrasonic Disperser [Heelscher Company] 1mL to 1000L

Hielscher Company

Equipment capable of scaling up (5ml → 1000ml → 10L → 1000L) with powerful ultrasonic devices equivalent to ultra-high pressure jet mills.

Heilshar Company primarily designs and manufactures large and powerful ultrasonic equipment, providing lab equipment, prototype benchtops, and production-level equipment. Effective and energy-efficient technology is required to harness ultrasonic capabilities. Additionally, even with the same ultrasound, the results are completely different from immersion-type ultrasonic cleaners. It is the high amplitude and high surface strength of Heilshar's powerful ultrasound that enables this technology. We have obtained Japanese explosion-proof certification for models ranging from 2000W to 8000W. Until now, Heilshar ultrasonic equipment has achieved high output (50,000W), which was impossible with ultrasonic devices, and guarantees 24-hour continuous operation. Unlike shear mixers, ultra-high-pressure homogenizers, and stirring bead mills that use shear force, our method of dispersion is different. Through 100% cavitation caused by ultrasound, we can achieve results that were unattainable with shear force. <Applications> Nanodispersion of aggregates, reduction of particle size, extraction, emulsification, dissolution, chemical reactions (sonochemistry) <Sectors> Carbon materials, nanomaterials, paints, inks, pigments, fuels, chemicals, cosmetics, biology, food & beverages.

Inquire About This Product

Related Videos

basic information

Nano-sized particles exhibit unique properties, and nanomaterials have attracted the attention of scientists, researchers, and engineers. Physical properties such as optical and magnetic characteristics, specific heat, melting point, and surface reactions provide high potential for materials. However, the smaller the particles, the more difficulties arise in processing them. High-power ultrasound is often the only effective method to achieve nanoparticles. The effects of high-power ultrasound have enabled manifold applications in development, catalysis, electronics, energy, as well as in biology & medicine and materials chemistry. Hielscher powerful ultrasound enables the dispersion of the desired crushed nanoparticles (such as nanotubes, graphene, nanodiamonds, ceramics, metal oxides, etc.). Ultrasound-assisted precipitation, known as bottom-up synthesis, is an efficient method for creating pure nanocrystals with unique properties.

Price range

Delivery Time

Applications/Examples of results

1. Ultrasonic wet dispersion 2. Ultrasonic homogenization 3. Ultrasonic particle surface functionalization 4. Ultrasonic extraction and cell lysis 5. Ultrasonic emulsification 6. Ultrasound for chemical activation 7. Ultrasonic decomposition 8. Ultrasonic particle surface cleaning 1-1 Nanomaterial dispersion 1-2 CNT dispersion 1-3 Graphene oxide 1-4 Reinforced rubber 2-1 Thermoelectric nan powder 2-2 Nanodiamond 2-3 Ultrasonic dyeing 3-1 Mini-emulsion 3-2 Conductive ink 4-1 NOx reduction by emulsification 4-2 Sonochemical desulfurization 4-3 Biodiesel

Line up(6)

| Model number | overview |

|---|---|

| UP200Ht & UP200St (Output 200W) | Sample volume: 0.01-1,000 ml With a conversion efficiency of over 90%, it performs dispersion and agglomeration disintegration of materials. Equipped with high-performance control technology, it enables stable operation under various conditions. Additionally, the parameters used can be repurposed for scale-up, making it suitable for development into larger machines. Compact and compatible with both handheld and stand-mounted configurations. |

| UP400St (Output 400W) | Sample volume: 5-2,000 ml Despite its 400W output, it does not generate internal heat, allowing for high-power operation. It is ideal for initial research aimed at future mass production (such as UIP10000/10000W). Its compact one-box design allows for installation in various locations (100V). It can scale up to large machines with outputs of up to 16,000W, suitable not only for research purposes but also for production equipment. |

| UIP1000hdT (Output 1,000W) | The ultrasonic processors UIP500hdT (500W) and UIP1000hdT (1,000W) have a completely sealed structure as they do not require any air-cooling fans for the internal converter cooling (a testament to high-efficiency ultrasound). The processor body is made of aluminum and can handle continuous liquid processing using a flow cell. Depending on the purpose, it can process up to 100 liters of liquid per hour. |

| UIP2000hdT (Output 2,000W) | The ultrasonic processor UIP2000hdT (Output 2,000W) has immense power while maintaining a completely sealed structure. It adopts a cascade sonotrode design and can expand the ultrasonic irradiation area, making it a suitable model for processing applications. It supports liquid processing for dispersion (dispersion of solid particles in liquid), anti-agglomeration (nano-level particles), emulsification (submicron diameter), crushing, reaction promotion (enhancing crystallization and growth in contact reactions), and cleaning. |

| UIP4000hdT (Output 4,000W) | The ultrasonic processor UIP4000hdT (Output 4,000W) has the maximum power when applying the required ultrasonic output obtained from UIP1000hdT and UIP2000hdT to the process line, making it suitable for scale-up. The processor body is made of stainless steel, and the electrical box comes standard in a dedicated cabinet. It prevents the intrusion of dust, heat, and active gases from the outside during installation in the factory. |

| UIP16000 (Output 16,000W) | The ultrasonic systems UIP10000 (Output 10,000W) and UIP16000 (Output 16,000W) are the largest models among ultrasonic processors. The processor, electrical box, and piping are integrated within the cabinet. In this class, some cooling of the processor is done via water cooling, but the hard sound wave efficiency can consistently maintain over 80%. |

catalog(7)

Download All Catalogs

News about this product(1)

Company information

DKSH is a member of the Swiss global company "DKSH Group." It provides comprehensive services and solutions across the entire value chain, combining procurement, marketing, sales, distribution, and after-sales service, through its three business divisions: consumer goods, production materials, and technology, with a long-term perspective.

![Deburring Machine "Twin Baritor" [Eligible for Small and Medium Enterprise Productivity Investment Subsidy]](https://image.mono.ipros.com/public/product/image/6d3/2000308654/IPROS16685940644635288329.png?w=280&h=280)