Formic Acid Reduction Reflow Device [Case Study: Temperature Variation within the Substrate]

Solve it with the Unitemp reflow device! Achieve rapid heating! No more worries about damage from unexpected temperatures!

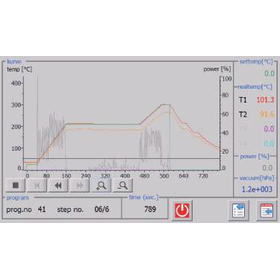

Recent circuit boards are equipped with a wide variety of components, including extremely small chip components, large components, as well as module boards and BGA packages. Since each component has a different thermal capacity, by the time the temperature of the larger components rises, it may exceed the heat resistance temperature of the smaller components, potentially causing defects. If such occurrences happen frequently, it could also affect the yield. Our reflow equipment can rapidly increase the temperature on the heating plate and is designed to avoid overshoot, thereby reducing thermal stress on printed circuit boards and mounted components. Additionally, the entire heating plate is automatically controlled to maintain a uniform temperature, which helps minimize temperature variations affecting the target objects, such as circuit boards. *For more details, please refer to the PDF document or feel free to contact us.*

Inquire About This Product

basic information

【Case Overview】 ■Issue: Temperature variation within the substrate ■Solution - By providing appropriate thermal energy, an environment that is less prone to overshoot is created. - The heater is controlled by a unique algorithm to ensure that the in-plane temperature variation on the heating plate is within ±1.5%. *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(6)

Download All CatalogsCompany information

We sell and provide maintenance for a benchtop vacuum solder reflow device that enables soldering without flux and voids, as well as a benchtop vacuum process high-speed heating furnace that achieves annealing in various chamber environments such as vacuum and process gas environments.

![[Reflow Equipment Case Study] Temperature Variation within the Substrate](https://image.mono.ipros.com/public/catalog/image/01/ba2/675680/IPROS05055255908461765313.jpeg?w=120&h=170)

![Formic Acid Reduction Reflux Device [Case Study: Flux Residue]](https://image.mono.ipros.com/public/product/image/08b/2000750667/IPROS02087092152301234872.png?w=280&h=280)

![Formic Acid Reduction Reflow Device [Case Study: Characteristics of Reflowed Solder]](https://image.mono.ipros.com/public/product/image/926/2000750680/IPROS53358226009125441763.png?w=280&h=280)