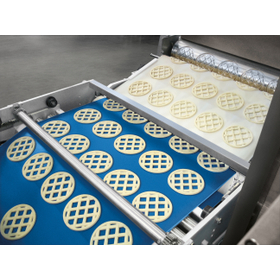

Add water and mixed flour to the noodle belt popper! Beautiful high-quality shumai will be formed.

The "DEC-100S" is a molding machine that fully automates the entire process from noodle sheet formation, precise filling, molding, to discharge. By pouring water and mixed flour into the noodle sheet popper, it automatically creates skins of the specified dimensions. Filling and molding are performed on a turntable, resulting in beautifully shaped, high-quality shumai that comes out on the discharge conveyor. 【Features】 - Accurate measurements and beautiful shapes - Minimal kneading of the filling - Quiet operation - Washable with water *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Specifications】 ■Production capacity: 6,000 pieces/hour (double line) ■Product size: 12–40g ■Machine size: 1,370×920×1,950 (W×L×H) ■Power consumption: 1.0kW *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Daiei Giken Co., Ltd. has been producing various food forming machines, including spring roll forming machines, gyoza forming machines, and shumai forming machines, since its establishment in 1970, when mechanization was difficult. To meet our customers' needs, we have established a consistent system for design, development, and production in-house, carried out by highly skilled staff. Additionally, by providing thorough aftercare and continuously striving for technological advancement, our food forming machines are now exported to countries around the world. Moving forward, our food forming machines will continue to evolve to deliver "deliciousness" to everyone.