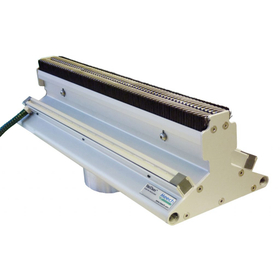

Small twin-screw extruder suitable for the development of thermosetting resins.

For the automotive industry, including friction materials and powertrain-related components! A compact twin-screw extruder with high durability and heat resistance!

This product is a compact twin-screw extruder suitable for the development of high-cost thermosetting resins. Conventional small twin-screw extruders are weak in strength and have issues such as being unable to achieve high mixing due to high torque, but this device has overcome these problems. It has approximately twice the torque compared to our previous models. 【Features】 ■ Suitable for the development of high-cost thermosetting resins ■ High durability and heat resistance ■ Excellent dimensional stability and electrical insulation ■ Lower cost than metals ■ Resin properties: delicate temperature management and shear force adjustment are required *For more details, please refer to the related links or feel free to contact us.

Inquire About This Product

basic information

【Proposal Example】 ■Issue - The resin hardened in the single-screw extruder, making extrusion impossible. ■Proposal - Suggested extrusion using a twin-screw extruder, including setting conditions. ■Result - Extrusion of the resin became possible. *For more details, please refer to the related links or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Usage】 ■For the automotive industry (friction materials, powertrain-related components, etc.) *For more details, please refer to the related links or feel free to contact us.*

Company information

PLABOR offers a wide range of products and services, focusing on plastic processing machines, film/sheet molding equipment, and tube/pipe molding equipment, as well as various manufacturing devices and manufacturing technologies. We also provide solution services that propose and supply various molding lines for extruders. Please feel free to contact us if you have any inquiries.

![[Examples of Achievements / Customer Feedback] STEER Twin-Screw Extruder / Omega Series.](https://image.mono.ipros.com/public/product/image/425/2001130501/IPROS13066920517261719058.jpg?w=280&h=280)