Pro Manual! Zero Defect Outflow Countermeasures Quality Improvement Techniques [Complete 8 Series]

On-site practical guide and procedure manual.

Consists of 8 types of manuals including quality improvement methods and tools that can be used on-site. <Free: Forms and mini-guides useful for quality improvement>

Takasaki Monozukuri Technology Research Institute's "Immediately Usable Series (1)" This manual consists of the following eight types: - Quality control methods to achieve zero market leakage troubles - Collection of case studies for preventing recurrence of quality issues - 4M management procedure manual for manufacturing sites - Human error countermeasure procedure manual for manufacturing sites - Course on measures to escape from whack-a-mole situations - Procedure manual for creating complaint response documents (defective product reports) - How to conduct "5 Whys Analysis" usable in manufacturing sites - Best 5 examples of Poka-Yoke (soft and hard)

Inquire About This Product

basic information

Detailed support menu to pave the future of small and medium-sized manufacturing industries ■ Online Young Leader Factory Management Skills Improvement Seminar (4-part series) http://factorysupport-takasaki.com/article/493421683.html ■ Ready-to-use Pro Manual (for self-study, training young employees, on-site improvement guide) http://factorysupport-takasaki.com/article/424984376.html ■ Affordable Subsidy Application Support Support for business restructuring subsidies / manufacturing subsidies / overseas supply chain diversification projects, etc. http://factorysupport-takasaki.com/article/498424788.html ■ Manufacturing Support Plastic prototype mold design and production (automotive, medical), ultra-gloss painting (piano black) http://shanghai-swifttech.com/ ■ Free Online Consultation https://mailform.mface.jp/frms/bintian/8s3ieuzwsa8f

Price information

Download version PDF data: 8,000 yen DVD version PDF data: 10,000 yen (including shipping) <Payment methods: Credit card / Bank transfer>

Price range

P1

Delivery Time

P3

Applications/Examples of results

As an in-house training text As a self-development text As a guide for quality improvement in production sites Please use it for practical human resource development and quality improvement in various manufacturing industries.

Detailed information

-

Table of Contents Chapter 1 Quality Building Techniques in Upstream Engineering 1. Three Reasons for Defective Outflow 2. New Product Launch Procedures 3. Error Proofing and the Swiss Cheese Model 4. Bottom-Up Design Methods 5. Creating Correct QC Process Charts and Manufacturing Preparation 6. Work Observation and Work Improvement Checklist 7. Toyota's Self-Completion Mechanism Chapter 2 Knowledge Management Techniques for Past Troubles 1. Overview of Knowledge Management Techniques 2. Key Management Item Extraction Table 3. List of New Change Points 4. List of Failure Modes 5. Failure Mode Extraction Table 6. QA Network Table 7. Management Point and Inspection Point Matrix Table 8. System of Quality Information Knowledge System Chapter 3 Standardization and Work Training Techniques 1. Standardization Techniques Using Checklists 2. How to Create Work Standards 3. Work Breakdown and Training Techniques Using TWI 4. Making Rules a Daily Habit Chapter 4 Management Techniques for Daily Operations 1. Cycle of Daily Management 2. Four Skills Required of Managers 3. Visualization Techniques for Change Points Chapter 5 Immediate Recurrence Prevention Measures on the Shop Floor 1. Why-Why Analysis Techniques for Work Sites Case 1: Contamination of Unprocessed Goods 2. Defective Cause Mapping Method for Feedback to Upstream Processes Case 2: Ceramic Fan Heater Fire Incident

-

Introduction Chapter 1 Corrective Actions and Preventive Measures 1 Error Proofing 2 Causes and Measures of On-Site Rules/Common Rules 3 Cause Investigation and Measures Using the 5 Whys Method 4 Correction/Prevention of Recurrence/Horizontal Deployment 5 Countermeasure Document Format Chapter 2 Various Analysis (Cause Analysis) Methods 1 Logical Thinking 2 5 Whys Analysis 3 Cause and Effect Diagram 4 FTA Analysis 5 Troubleshooting Method 6 QC Story 7 4M5E Analysis Chapter 3 Case Studies of Quality Trouble Measures Case 1 Operational Errors Case 2 Picking Errors of Difficult-to-Distinguish Products Case 3 Process Skipping Due to Work Interruptions Case 4 Inadequacies in External Submission Documents Case 5 Violations of Work Instructions During Transfer to Overseas Factories Case 6 Neglecting Problems Case 7 Recent Frequent Work Errors in the Process Case 8 Ensuring Compliance with Established Procedures Case 9 Contamination with Unprocessed Materials Case 10 Smoke Issues with Products Passing Shipment Inspection Case 11 Variability in Component Processing Characteristics Case 12 Issues with Injection Molding Specific Technologies Case 13 Foreign Matter Adherence in Multiple Processes Case 14 Machine Failures Case 15 Chronic Defect Measures Case 16 Component Damage Defects in the Market Case 17 Abandonment of the Three Gen Principles and Misuse of Methods

-

Table of Contents 1. Before Getting to the Main Topic 2. What is the Rule Pyramid? 3. Why Do Defects Occur? 4. Management Deficiencies in Special Processes 5. Cause Investigation and Countermeasure Procedures Based on Rules 6. Why-Why Analysis Procedure for Use on the Shop Floor 7. Analysis Procedure Using the Defect Cause Mapping Method 8. Analysis Procedure Using the Two-Stage Defect Cause Analysis Method 9. Format for Defect Countermeasure Report (for Submission) 10. Investigation of Human Error Causes and Countermeasure Procedures 11. Case Studies

-

Introduction Chapter 1 Systematic 4M Management Procedures 1. Purpose of 4M Management 2. Definition of 4M Management Targets 3. Ranking 4. 4M Management Flow 5. Management of Design Changes and Process Changes 6. Initial Flow Management 7. Management of New Production Start-up 8. Daily Change Management 9. Visualization of Change Points 10. Monitoring of Critical Factors and Critical Characteristics Chapter 2 Understanding Change Points through Statistical Analysis Methods 1. Stratification and Sampling 2. What is Variation? 3. Understanding Process Capability and Variation Management 4. Identifying Change Points using Control Charts Chapter 3 4M Change Management in Partner Factories 1. Issues in Quality Management of Partner Factories 2. Agreements with Partner Factories 3. Evaluation and Rating of Partner Factories Chapter 4 Application of 4M Management 1. 4M Management in Low-Volume, High-Variety Production 2. Special Process Management 3. Traceability Management 4. Capturing Change Points through the Use of IoT

catalog(6)

Download All Catalogs![Collection of Case Studies on Measures to Prevent Recurrence of Quality Issues [Pro Manual for Immediate Use on Site] <Free: Format Forms and Mini Explanations>](https://image.mono.ipros.com/public/catalog/image/01/6ce/621233/IPROS11824442873992560674.jpeg?w=120&h=170)

![4M Management Procedure Manual for Manufacturing Sites [Pro Manual for Immediate Use on the Ground] <Free: Format Form & Mini Explanation>](https://image.mono.ipros.com/public/catalog/image/01/b62/636038/IPROS31123171734985812383.jpeg?w=120&h=170)

![Human Error Prevention Procedure Manual for Manufacturing Sites [Pro Manual for Immediate Use on Site] <Free: Format Template & Mini Explanation>](https://image.mono.ipros.com/public/catalog/image/01/12c/636039/IPROS71398125840504913444.jpeg?w=120&h=170)

![How to Conduct "5 Whys Analysis" Usable in Manufacturing Sites [On-Demand Distribution Field Leader Training Text] <Free: Format Form & Mini Explanation>](https://image.mono.ipros.com/public/catalog/image/01/99a/645838/IPROS49202434649489209457.jpeg?w=120&h=170)

![Poka-Yoke (Soft_Hard) Case Studies Best 5 [Pro Manual for Immediate Use on Site] <Free: Format Forms & Mini Explanations>](https://image.mono.ipros.com/public/catalog/image/01/46c/657692/IPROS42733908146846401220.jpeg?w=120&h=170)

Company information

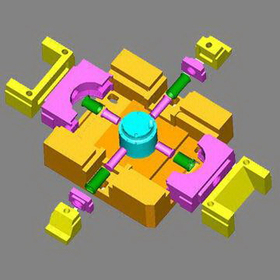

■Company Name: Takasaki Swift Technology Solutions Co., Ltd. ■Established: March 1, 2014 ■Company Incorporation: August 15, 2017 ■Representative: Representative Employee Kanou Hamada ■Capital: 2 million yen ■Sales: 20 million yen ■Main Business: Manufacturing Technology Consulting (Quality Improvement/Productivity Enhancement) ● Subsidy Application Support (Restructuring Subsidy, Overseas Supply Chain Resilience Subsidy, etc.) ● Contract Design and Manufacturing of Molds, etc. (Prototype Molds, Parts Machining, Glossy Coating, etc.) ● Manuals and DVD Series for Immediate Use on Site (On-site Handbooks, Self-Learning, Employee Training Texts) ● Seminars (For Young and Mid-Career Employees / For Managers) ● Quality Improvement Support (Quality Improvement, New Product Launch, Contract Manufacturing)

![[Case Study] Kobayashi Manufacturing Co., Ltd.](https://image.mono.ipros.com/public/product/image/869/2000361957/IPROS4276185379211513833.jpg?w=280&h=280)

![[Data] Liquid-cooled heat exchanger (liquid-liquid) / Apiste](https://image.mono.ipros.com/public/product/image/d6a/2000639677/IPROS70932606551808122289.jpeg?w=280&h=280)

![[Data] The Necessity of Non-Freonization / Apiste](https://image.mono.ipros.com/public/product/image/7e9/2000641109/IPROS09660173382881672400.jpeg?w=280&h=280)

![[Book] Design, Fabrication, and Applications of Metamaterials (No. 2146BOD2)](https://image.mono.ipros.com/public/product/image/c11/2000696666/IPROS04971285555119062416.jpeg?w=280&h=280)