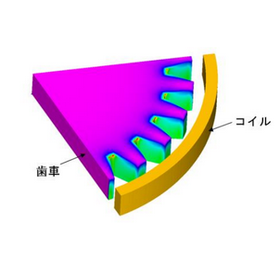

[Analysis Case] Predicting the magnetization distribution within a plastic magnet from measurement data.

Estimating the magnetization distribution from the numerical data of magnetic flux density obtained from the forward problem! Introducing an analysis case of the inverse problem.

The case of analyzing the magnetic field created by magnets and coils is called a forward problem. On the other hand, the problem of determining magnetization or current from the magnetic field distribution is called an inverse problem. In this instance, we will introduce a case where we estimate the magnetization inside a magnet from numerical data of the magnetic flux density on the surface of a plastic magnet, and analyze the magnetic flux density created by that magnetization (inverse problem). For convenience, we will estimate the magnetization from the magnetic flux density obtained through the forward problem and calculate the magnetic flux density at a different location. Since we will use the results of the forward problem, we can compare the results of the forward and inverse problem analyses and evaluate the validity of the inverse problem analysis function. [Case Overview] ■ Software Used: PHOTO-MAGTZ ■ Analysis Results - The magnetic flux density at a position 1mm away from the surface of the magnet is generally consistent between the forward and inverse problems. - There are multiple magnetization distributions that show the same magnetic flux density. *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

At Photon, we are developing "electromagnetic field analysis software" that models and simulates products and components utilizing electromagnetic phenomena on a computer. In traditional design and development environments, the process has primarily revolved around trial and error through prototyping based on the experience of engineers and experiments with prototypes. However, conducting experiments using actual prototypes and analyzing the results requires significant time and cost. Moving forward, transitioning from an experimental and prototyping-based approach to an analysis-based design approach will be a crucial challenge for improving productivity, and establishing simulation technology as the core of analysis-based design techniques will be essential. In this context, Photon is developing and providing "analysis software" focusing on electromagnetic fields, as well as heat, vibration, and sound fields. By utilizing Photon's software, efficient development and design of various industrial products can be achieved. In this way, Photon aims to support users in reducing the number of prototypes, lowering development costs, and shortening development periods in their manufacturing environments, ultimately enhancing their competitiveness.

![[Analysis Case MAGTZ-1] Predicting the magnetization distribution within a plastic magnet from measurement data (inverse problem)](https://image.mono.ipros.com/public/catalog/image_generated/01/3a5/312628/312628_IPROS93619000465067175_1.jpg?w=120&h=170)

![[Case Study] Electromagnetic Wave Analysis of Waveguides Using Slide Interfaces](https://image.mono.ipros.com/public/product/image/d8b/2000060365/IPROS19979134950592281117.gif?w=280&h=280)

![[Analysis Case] Calculation of Electromagnetic Force in the Plunger Model](https://image.mono.ipros.com/public/product/image/149/2000060395/IPROS43160246470680152775.gif?w=280&h=280)

![[Analysis Case] Frequency Response Dynamic Magnetic Field Analysis of Magnetic Shielding](https://image.mono.ipros.com/public/product/image/68b/2000763926/IPROS02180885106606877203.png?w=280&h=280)

![[Analysis Case] Electromechanical Coupled Analysis of Cylindrical Piezoelectric Elements](https://image.mono.ipros.com/public/product/image/c82/2000766440/IPROS89777163338614210402.png?w=280&h=280)

![AI Platform for Materials Informatics [Simplified Version]](https://image.mono.ipros.com/public/product/image/fea/2000694275/IPROS77432742864447267527.jpeg?w=280&h=280)

![[Technical Data] How to Determine the Internal Clearance Dimensions of Rolling Bearings for Motor Shafts](https://image.mono.ipros.com/public/product/image/b5e/2000607337/IPROS83752919306087419855.png?w=280&h=280)