Fully automated AI appearance inspection combining object detection and robotics.

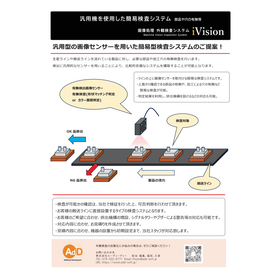

This is an appearance inspection software that utilizes AI object detection technology. It is capable of inspecting the appearance of a wide variety of workpieces, including metal processed products, films, resin molded products, and printed materials. (Examples: scratches, foreign objects, chips, color unevenness, missing characters, etc.) By combining it with industrial robots, it achieves a reduction in manual visual inspections.

Inquire About This Product

basic information

- No specialized knowledge in AI or programming is required - One software handles everything from shooting to judgment - Capable of detecting defects in a wide variety of objects depending on training - Complete automation by combining with industrial robots! If you're unsure whether inspections can be done with AI but would like to see it first, please feel free to consult with us!

Price range

Delivery Time

Applications/Examples of results

Automation and Quality Improvement of Appearance Inspection for Scratches, Foreign Objects, Chipping, Color Variations, Missing Characters, etc. Case 1: Adoption for Appearance Inspection of Injection Molded Products We achieved the very high-level request to automatically detect scratches and foreign objects of micron order or more on the surface of injection molded products (translucent flat plate work). ◎ Application: Can also be applied to items with high uniformity where defect locations cannot be specified, such as films and steel plate coils. Case 2: Parts Inventory Management System (In-house Development) Quickly counts the inventory of parts scattered in cases, such as parts bins. A business efficiency system realized with the minimum configuration of a camera stand, USB camera, and PC. Features: ◎ Can detect even if the orientations are mixed. ◎ Can detect only the target even if different types are mixed in.

catalog(6)

Download All CatalogsCompany information

Our company is a manufacturer that designs and produces custom-made testing, measurement, and control systems as a problem-solving partner for major corporations. We engage in work related to advanced technologies that support Japan's manufacturing and contribute to technological innovation across a wide range of industries, including national research institutions and universities. We strive to design and develop products that satisfy our customers by leveraging our technical expertise in hardware and software, and we have a proven track record of producing numerous measurement systems. In particular, as an alliance partner of National Instruments in the United States, we excel in system integration centered around LabVIEW. In 2017, we received the Software Engineering Award, recognizing our top-class technical capabilities. In 2000, we obtained ISO 9001 certification (registration audit) for our products, further solidifying our quality assurance system. Our proprietary product, SmartEdge (a two-dimensional automatic measurement device), is designed to automatically measure the dimensions of flat-shaped workpieces such as films. We offer a wide range of products from tabletop models to large sizes. We are also focusing on research and development to contribute to further improvements in inspection efficiency for our overseas users.

![Company Information Brochure [Chuo Electric Instrument Manufacturing Co., Ltd.]](https://image.mono.ipros.com/public/catalog/image/01/3a0/594357/IPROS31134438763805035859.jpeg?w=120&h=170)

![[AI Image Inspection Case] Monitoring of Manufacturing Machinery](https://image.mono.ipros.com/public/product/image/a47/2001481519/IPROS14997574167334648291.png?w=280&h=280)

![[AI Image Inspection Case] Judgment of Errors in QR Codes](https://image.mono.ipros.com/public/product/image/1d8/2001502452/IPROS4274665440765173355.png?w=280&h=280)