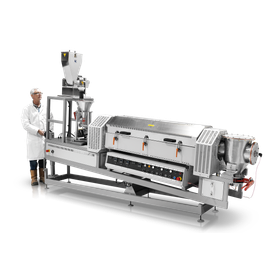

Far superior to conventional rotary kilns! Achieves continuous uniform heat treatment.

The "SGV Type Rotary Kiln" is a device suitable for high-precision continuous uniform drying and heat treatment of fluid powder and granular materials. It accommodates a wide range of powdered and granular materials, including battery materials, ceramic materials, carbon, and resin materials. Additionally, we provide a compact device that meets your requests for selecting the appropriate material for the furnace core tube, controlling temperature, time, and atmosphere, as well as automating supply and discharge. 【Features】 ■ Achieves multi-temperature zone heat treatment with temperature control for each zone using a single unit ■ Capable of processing large quantities in a compact furnace ■ Allows for the introduction of drying air and atmosphere control ■ The material of the furnace core tube can be selected according to application (SUS304/316, Inconel, etc.) ■ Automation of supply and discharge, return of collected dust, and temperature measurement are also possible *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Demonstration unit available for proof testing】 ■ Customers with the following concerns are encouraged to inquire: - Is drying and heat treatment possible with a rotary kiln method? - What are the time and temperature parameters for heat treatment? - I would like to determine the size and specifications of the production machine. *For more details, please refer to the PDF document or feel free to contact us.*

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Since our establishment, we have consolidated various technologies cultivated through extensive experience, including "thermal control technology," "airflow control technology," "air pollution prevention technology," "mechanical design technology," and "engineering capabilities," to propose optimal systems tailored to our customers' needs, ranging from individual equipment to plant machinery.

![[Case Study] Adopted for Stainless Steel Processing: "Batch-Type Rotary Kiln"](https://image.mono.ipros.com/public/product/image/aef/2000741056/IPROS16569166662805583410.png?w=280&h=280)

![Butterfly Valve BV Series [2D/3D CAD]](https://image.mono.ipros.com/public/product/image/7a0/2000815776/IPROS65074472961613162442.jpeg?w=280&h=280)

![Challenging Decarbonization Technologies! Introduction to the Thermal Technology Research Institute [Latest Information for 2025!]](https://image.mono.ipros.com/public/product/image/3d5/2000834196/IPROS99631596500298700026.jpeg?w=280&h=280)

![Venturi Mixer VM Series [2D/3D CAD]](https://image.mono.ipros.com/public/product/image/d2e/2000852305/IPROS58786938329892851049.png?w=280&h=280)

![Control Butterfly Valve BVC [2D/3D CAD]](https://image.mono.ipros.com/public/product/image/42a/2001089801/IPROS60217385225753115405.jpeg?w=280&h=280)