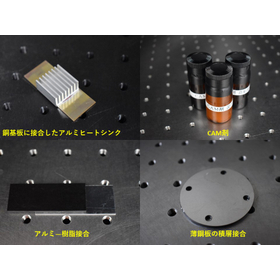

Thermal measures during material bonding and joining, and CAM bonding suitable for laminated bonding and joining.

Are you having trouble with heat dissipation improvement during component bonding or with adhesion and joining when laminating metals?

CAM joining is a joining technology that utilizes two joining mechanisms, "Chemical & Melting," to bond materials. It resembles an adhesive but is not an adhesive. The joining targets can include a wide range of materials, such as metal-plastic and dissimilar metals. CAM joining is an environmentally friendly technology that allows for easy construction and cost reduction, and it can be designed to have various functions depending on the joining purpose.

Inquire About This Product

basic information

Functional characteristics of CAM bonding include: - Capability for metal-resin bonding - Capability for metal-metal bonding including dissimilar metals - Applicable to most metals that undergo surface oxidation - Bonding possible using organic thin films, with low consumption - Capability for zero thermal resistance bonding - High heat resistance of over 150°C - CAM agents are water-soluble bonding materials but can be bonded after drying - Options for conductivity and insulation These features provide a variety of functional characteristics.

Price range

Delivery Time

Applications/Examples of results

CAM bonding is suitable for heat sink applications that can take advantage of low thermal resistance and for the laminated bonding of thin metal sheets.

Company information

Our company is engaged in the development of joining technologies. The newly developed CAM joining can handle a range of applications, starting from the joining of dissimilar materials such as metal and resin, to metal-metal joining that includes dissimilar metals. CAM joining can achieve zero thermal resistance and is also applicable to the laminated joining of multilayer thin plates.

![[Case Study Presentation] CAM Joining Enabled Dissimilar Material Bonding with Low Thermal Resistance](https://image.mono.ipros.com/public/product/image/146/2001502278/IPROS11074528976109451525.png?w=280&h=280)