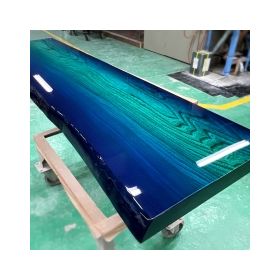

The highest quality mirror finish created by honing techniques.

One of the factors that determines the quality of a mirror finish is the level of sharpening technique. Therefore, this time we will introduce the process of fine grinding using a belt sander for "urethane mirror finish."

Inquire About This Product

basic information

For more details, please visit our website at https://www.piax.co.jp/.

Price range

Delivery Time

Applications/Examples of results

Piax has been dedicated to woodworking finishes for 60 years, with a proven track record of painting over 80 types of wood and a vast accumulation of know-how. Wood has its own characteristics, such as deep vessels, high resin content, and oil content, depending on the type. While manuals can be applied to artificial materials (like resin and metal), achieving a beautiful finish on wood requires painting methods and processes tailored to each wood type. Additionally, the amount of moisture contained in the wood affects the penetration of the paint and the quality of the finish, significantly impacting the durability of the coating. In order to provide the highest quality finishes that are both aesthetically pleasing and functional, we strive daily to refine our techniques. Please feel free to contact us for consultations or requests for estimates regarding painting.

Detailed information

-

1) Primer The primer serves the purpose of sealing and stabilizing the substrate, providing a sense of thickness to the topcoat applied in the next step. Primer paints are more flexible than topcoat paints, allowing them to adapt to the swelling and contraction of the substrate, and they excel in impact resistance, adhesion, and resistance to paint film cracking.

-

2) Lower sanding This is an important process that lays the foundation for creating a smooth topcoat, significantly affecting the final finish. It involves sanding with a belt sander, followed by adjustments with a hand sander.

-

Topcoat After spraying white enamel, a clear coat is applied. As this is the final step in the painting process, it determines the finishing appearance in terms of smoothness, gloss, and color.

-

Finally, we are at the polishing stage. The substrate this time is a few millimeters thick drywall, which will be used for wall panels. Since it will be finished on one side, it is important to take measures against warping. Marking is also essential to ensure there are no areas left unpolished.

-

The belt sander used this time is a machine that has been in operation for over 30 years since it was used to paint pianos. It has been modified to be able to grind up to the size of w1450×d5000×h650.

-

The surface is polished by pressing down with a pad on a belt-like paper that is rotating with a motor. It is the craftsman's skill to evenly apply the paper so that no unevenness remains on the surface.

-

We will replace the coarse paper with fine paper. We will choose the grit of the paper according to the paint and materials. This time, we used two types of paper.

-

Belt sanders can efficiently and uniformly sand a larger area compared to hand sanders. By using large machinery, we achieve high quality and short delivery times.

catalog(1)

Download All CatalogsCompany information

"Painting Mirror Finish in the Heart of the Piano Industry: Hamamatsu" Hamamatsu City in Shizuoka Prefecture is home to world-renowned piano manufacturers. Our company has established a painting factory in Hamamatsu and has a track record of 30 years in subcontracting painting for both large and small piano manufacturers since our founding. For 60 years since our establishment, we have diligently honed our painting skills. Currently, we utilize our piano painting technology to create custom furniture, store fixtures, interior doors, wall panels, and more, focusing on unique items for brand shops, residences, luxury apartments, and commercial facilities, bringing joy to many customers. We also receive many requests from other specialized painting contractors, particularly for mirror finish painting, where we are trusted with high-volume and complex shapes, as well as projects requiring the highest quality. They say, "We can't handle it ourselves, so if we ask PIAXX, we can trust the quality and delivery!" In the heart of the piano industry, Hamamatsu, we have a "Hamamatsu Monozukuri Meister" certified by the mayor of Hamamatsu. PIAXX's painting technology provides additional value to our customers' products and technologies.

![[Stainless Steel Processing Case] Stainless Steel Plate, Mirror Finish](https://image.mono.ipros.com/public/product/image/d2c/2001219827/IPROS90330082948014805840.png?w=280&h=280)

![[Leveling Correction] Leveling correction of concrete floors "Teratec Method"](https://image.mono.ipros.com/public/product/image/d08/1267539002/IPROS70063422645318547243.jpeg?w=280&h=280)

![[Case Study] Construction Example of High-Temperature Facilities in Factories Using High-Performance Heat Insulation Sheets](https://image.mono.ipros.com/public/product/image/962/2000579577/IPROS04218491152233419232.jpeg?w=280&h=280)