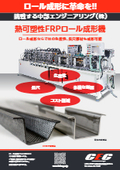

Thermoplastic FRP long products can be molded with a roll forming machine equipped with heating functions.

Molding of long products that cannot be formed by pressing has also become possible in a short time. Roll forming of thermoplastic FRP sheets such as CFRTP!

Our company offers a "roll forming machine" that can quickly shape long products from thermoplastic FRP sheets, such as CFRTP, into their final cross-sectional shapes. The process includes a preheating stage to heat and soften the material, a forming stage to impart the shape, and a cooling stage to cool the formed product. The sheet material is inserted through the material inlet, and shaping and feeding are performed simultaneously using a roll mold. After going through these processes, the material is shaped into its final cross-sectional form. It is possible to set the temperature of the roll mold for each stage, allowing for the optimization of conditions for various thermoplastic FRP formations. 【Features】 ■ Productivity ■ Long lengths ■ Diverse cross-sections ■ Cost reduction *For more details, please refer to the PDF materials or feel free to contact us.

Inquire About This Product

basic information

【Specifications】 ■Molding speed: 0.5 to 3.0 m/min ■Material plate thickness: t1.0 to 3.0 ■Roll mold setting temperature range: 50 to 220℃ *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Chubu Engineering Co., Ltd. is a company that primarily designs and manufactures equipment and molds for roll forming and bending processes. As a specialist in plastic processing technology, our company is committed to the spirit of "together with our customers" and aims to advance "more evolved technology" as our corporate policy, supporting our customers' better production activities.

![Burr Removal Machine "Baritor IV" [Eligible Model for Small and Medium Enterprises Productivity Investment Subsidy]](https://image.mono.ipros.com/public/product/image/7e6/2000308307/IPROS7133207276557527838.png?w=280&h=280)

![Burr Removal Machine "Triple Baritol" [Eligible for Small and Medium Enterprise Labor-Saving Investment Subsidy]](https://image.mono.ipros.com/public/product/image/fbb/2000308526/IPROS10846500360243567721.png?w=280&h=280)

![The first step in automating factories and warehouses starts with floor leveling [with case studies included].](https://image.mono.ipros.com/public/product/image/8e6/2001522448/IPROS11175175298099575604.png?w=280&h=280)