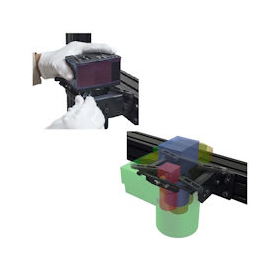

Line lighting fixed base compatible with Line Camera. Fixes lighting of different shapes.

Image Inspection Dedicated Platform (Camera Stand) FLEX-L Series

It is possible to adjust the angle of the optical condition settings, which are important for the operation of the Line Camera, at the appropriate locations. Lighting with different mounting can be securely fixed using a unique mounting mechanism.

The line lighting mounting fixed chassis has a slide-variable fixing mechanism, allowing it to be secured from a minimum screw pitch of 28mm to approximately L500 type nut rail line lighting. It is also possible to adjust and fix the angles of flat lighting, reflectors, and projection boards. It can be used as transmitted lighting installed on a base plate or as reflected lighting installed on a lighting column, and the angle adjustment screw can be operated from one direction, making it easy to operate even in limited surrounding spaces during transmitted lighting. The line lighting fixed chassis is part of the FLEX-L series, which also includes a fixed chassis (camera fixed chassis) for line scan cameras/line sensor cameras equipped with the same angle adjustment mechanism. Additionally, there is a lineup of lighting fixed chassis suitable for industrial cameras/area cameras in the FLEX-A series, designed for image processing lighting and LED lighting. Dedicated site: imageprocessingenvironment.com (Selling nationwide in Japan through the website.)

Inquire About This Product

basic information

Features of FLEX-L for line scan and FLEX-A series for industrial cameras: 1. A mounting mechanism that allows direct attachment of cameras with unique sizes from various manufacturers and a wide variety of lighting without the need for additional brackets or mounting hardware. 2. An adjustment mechanism designed for image processing and optical conditions, placed where it is needed, considering the center of gravity. An angle-variable mechanism that can securely fix angles at intuitive locations. 3. As the specimen changes, the positions of the camera and lighting also change. A platform specialized for image processing environments that allows not only the movement of the main and auxiliary columns but also relocation to any position on the base plate. These systems are used for the following applications: - Sample testing, customer inspections, demonstration displays, and production equipment. Accurate persuasion during inspections, evaluation reports during transport, and the ability to conduct sample tests and production equipment inspections, as well as adaptation to changes in work and inspection methods after equipment installation. - Special equipment, research and development, measurement, and data collection. Operation of large cameras (customizable) and data testing at fixed positions. - Software development. As a delivery system platform for software products such as AI software and verification algorithm software.

Price information

FLEX-L Series Camera Mounting Frame: ¥39,900 (excluding tax) Lighting Mounting Frame: ¥47,800 (excluding tax) You can order from our website.

Price range

P2

Delivery Time

P3

Applications/Examples of results

FLEX-L Series: For image inspection applications using line scan cameras and optical condition trials - Image inspection sample work testing - Inspection table for optical inspection and testing equipment - Camera mounting (CoaXPress, Camera Link, GigE, USB, etc.), measurement device mounting - Lighting mounting (line, long line, etc.), mounting for reflectors, projection plates, etc. - Installation of transport mechanisms - Image processing software testing environment - Image processing algorithm development environment, AI software testing environment - High-strength inspection table

catalog(1)

Download All CatalogsCompany information

With 20 years of experience in image processing and optical technology, we provide and develop specialized equipment for image processing. Based on our experience in creating high-reliability, high-definition image processing devices such as image boards and defect inspection units, we continuously evolve our products with a "skillful" concept to adapt to the changing times. The FLEX-L and FLEX-A products are designed to address the rapid changes brought about by AI.

![[Case Study of hakaru.ai] Harima Bistem Co., Ltd.](https://image.mono.ipros.com/public/product/image/2076831/IPROS349262696834936412.png?w=280&h=280)