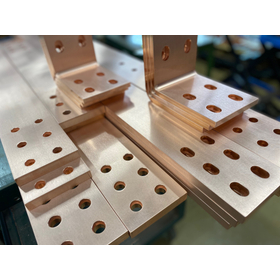

It may be possible to create the shape I had given up on! Copper can be welded.

I will introduce the difficulties and interesting aspects of welding copper to copper using copper. 【Welding Methods】 ■ Increase the current value for welding ■ Preheat before welding ■ Remove dirt and impurities from the welding area *For more details, please feel free to contact us.

Inquire About This Product

Related Videos

basic information

【Overview】 ■Material: Copper busbars and copper rods processing ・Procurement → Processing → Plating ■Dimensional Tolerance: Within general tolerance range ・Processing tolerance to be discussed ■Lot: 1 to 100 pieces ■Industry and Application: Heavy electrical industry, processing of electrical components related to panels ■Material Dimensions ・Specializes in copper busbars from 3mm to 20mm ・Has experience in lathe processing of copper rods from φ10 to φ55 ■Processing Machines and Methods: Press processing, machining, lathe processing ■Features ・Conclusion: Copper can be welded *For more details, please feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please feel free to contact us.

Company information

We have been providing copper components to transformer and control panel manufacturers, delivering energy through copper and ensuring safety and security for society. As a result of walking alongside our customers throughout this process, we have become a "copper specialty processing company"! When our customers are truly in need, we respond as quickly as the same day, embodying the spirit of mutual support! ■ Overwhelming inventory ■ Craftsmanship that allows for the fastest processing and youthful, energetic power ■ Strong network with local plating partner companies We can perform various processing methods such as machining, pressing, welding, and brazing. Since we have established a production system for a wide variety of small quantities, ■ Small lots ■ Various sizes ■ Complex shapes can also be handled quickly. We aim to be a company that delivers energy to everyone through copper, and we look forward to your continued support.