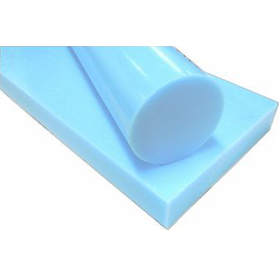

It is a silicone-like rubber material called AR-G1L. Output via 3D printing! Accepting commissioned modeling.

This is a silicone-like rubber material called AR-G1L, outputted from AGILISTA. It has a Shore hardness (A) of 35. Due to the use of water-soluble support material, it is capable of creating intricate shapes. With a layer pitch of 30μm, it features high precision and takes advantage of the properties of highly elastic materials, making it suitable for reproducing flexible thin-walled structures that are prone to breakage and difficult to replicate with conventional rubber-like materials. The silicone rubber material can be applied to assembly evaluations of gaskets, grip feel checks, the production of soft jigs, and models of soft organs and blood vessels. *Shore hardness (A) is measured by the manufacturer based on JIS K6253. Tests conducted in compliance with the following standards have passed: - REACH - RoHS

Inquire About This Product

basic information

Features: Resin, flexibility, soft Color: Semi-transparent, but the top and bottom surfaces have high transparency, while the sides have lower transparency due to layering. Texture: Smooth Hollow structure: Possible. However, a hole with a diameter of 2.5mm or more is required to remove support material. Please be aware that even if there are holes, it may not be manufacturable due to the model's structure. Manufacturing method: Inkjet Maximum build size: 297mm (height) × 210mm (width) × 200mm (depth) Estimated shipping time: 2 to 8 days

Price range

Delivery Time

Applications/Examples of results

Prototype Industrial product Functional prototype

catalog(1)

Download All CatalogsCompany information

DMM.make 3D printer output service is a 3D printing contract manufacturing service equipped with cutting-edge equipment. Please feel free to contact us! ■ Over 1,000 corporate usage cases We provide 3D printing for "prototypes" and "molds" using 3D printers, as well as "mass production" methods that do not require molds. Our services are utilized in manufacturing, construction, medical, aerospace, food, agriculture, and more. In recent years, there has been an increase in cases where 3D printed objects are used in final products! We are committed to solving our customers' challenges based on numerous examples, so please feel free to reach out. ■ Over 55 types of materials, the largest variety in the industry 〇 Metal 〇 Plastic 〇 Rubber 〇 Aluminum 〇 Stainless Steel 〇 Resin, etc. Please feel free to contact us to find out which material is most suitable for your desired performance. ■ More than 30 state-of-the-art 3D printers available 〇 Powder Sintering 〇 Inkjet 〇 Binder Jetting 〇 Stereolithography 〇 Ultra-fast Stereolithography, etc. We will propose which printing method is most suitable for your challenges. ■ Case study site https://make.dmm.com/print/case/biz/

![[Case Study] Construction Example of High-Temperature Facilities in Factories Using High-Performance Heat Insulation Sheets](https://image.mono.ipros.com/public/product/image/962/2000579577/IPROS04218491152233419232.jpeg?w=280&h=280)