We are Nitto Kousakusho Co., Ltd., engaged in precision machining in Osaka Prefecture.

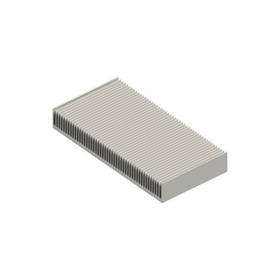

008【Our Technical Expertise】2024/08/15 ~Machining Case of Machined Heat Sinks: Deep Fin Grooves~ This time, we will introduce a successful machining case for small to medium lots of 30 to 50 pieces. The product name is heat sink, and the processing was carried out based on the following specifications. We received a request to manufacture a monolithic heat sink with fins machined out. In this processing, there was a challenge that the fins were prone to breakage during machining due to the deep fin grooves. However, leveraging our long-standing expertise in jig manufacturing and machining know-how, we were able to successfully complete and deliver the product. In particular, we quickly responded to the relatively small lot of 30 pieces and met the customer's requirements effectively. Our company provides reliable products with high technical skills even in small to medium lot metal processing and machining. ◎ If you have any inquiries regarding metal processing or machining, please feel free to contact us. We also welcome simple machining requests, so do not hesitate to consult with us. #MetalProcessing #Machining #SmallLotProduction #MediumLotProduction #PrecisionMachining #RotaryEngine

Inquire About This Product

basic information

- Fin thickness: 1mm - Fin height: 27mm - Groove width: 2mm - Material: Aluminum - Number of processed units: 30 pieces

Price range

Delivery Time

※If you have any inquiries regarding metalworking or machining, please feel free to contact us. We also welcome simple machining requests, so don't hesitate to reach out.

Applications/Examples of results

Heat sink

Company information

NITTO MFG. Co., Ltd. (Osaka), founded in 1965, has a long history as a designer and manufacturer of jigs and special-purpose machines. Today, we handle everything from one-off machining to small- and medium-lot precision parts production. Leveraging our unique expertise cultivated through jig and special machine development, we flexibly support prototypes and custom machining requests. Equipped with a wide range of facilities—from conventional milling and lathes to machining centers, NC lathes, and grinding machines—we can process diverse materials including iron, cast iron, aluminum, stainless steel, and copper. From the concept stage through design, manufacturing, finishing, and delivery, we provide a complete one-stop solution. If you face any machining challenges, please feel free to consult NITTO MFG. (Osaka). Furthermore, as part of our lifelong commitment, we actively engage in: Advancing precision machining technology through jig-design know-how Manufacturing and sales of our originally designed small Wankel rotary engines (NR Series) Development of next-generation rotary engines capable of operating on hydrogen and multiple fuels

![[Information] Points to Note in Quality Control - Revision Work Edition (Free Download Available)](https://image.mono.ipros.com/public/product/image/a82/2000731851/IPROS82473397545185370431.png?w=280&h=280)