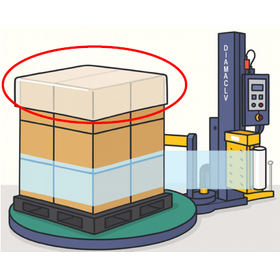

By simply placing it between pallets (mainly plastic pallets) and the items being loaded, it produces a significant effect in preventing cargo shifting.

Simply laying it on the pallet can easily prevent cargo collapse. It also contributes to reducing the use of existing stretch film and addressing environmental issues. When used in conjunction with our cargo collapse prevention band products, it exhibits even greater effectiveness in preventing cargo collapse. Reference items for placement: ☆General type (for lightweight items) ● Bags made of paper, polyethylene, etc. ● Cardboard and plastic cardboard cases ● Various containers (with flat bottom shapes) ● All types of paper products ☆Heavy-duty type ● Drums and one-gallon cans ● Bale cans ● Various containers ● Items with uneven bottom shapes

Inquire About This Product

basic information

【Specifications】 W900 x L600, W900 x L900, W900 x L1000, W900 x L1100 Roll length W900 x 25m W900 is fixed. For sizes other than the above L dimensions, please consult separately. 【Characteristics】 General Type Heavy Duty Type Specification Polyester filament + PVC foam Tensile Strength (Vertical) 58kg/30mm width 210kg/30mm width Tensile Strength (Horizontal) 68kg/30mm width 190kg/30mm width Tear Strength (Vertical) 24kg 102kg Tear Strength (Horizontal) 20kg 70kg Color Tone Dark Gray Light Gray Temperature Conditions -50℃ (Freezer) to Room Temperature

Price information

Please check with the retailer.

Delivery Time

Applications/Examples of results

【Usage Instructions】 - When placing between a pallet or items, please use one size smaller. *Example: Pallet size 1,100×1,100: Palemat W900×L1,000 - The use of the palemat is primarily intended for room temperature and indoor conditions. Please refrain from using it under physical conditions that require heat resistance, cold resistance (outdoor), water resistance, chemical resistance, oil resistance, or outdoor use. - Please conduct thorough testing for any unique usage by customers.

catalog(1)

Download All CatalogsCompany information

Our company's load securing band products were launched in 1990, pioneering the industry, and have been well-loved for many years. We now offer a wide variety of options, replacing traditional stretch film used for load securing with reusable bands, contributing to cost reduction, improved work efficiency, and addressing environmental issues by reducing plastic waste. For requests beyond standard products, we can accommodate custom orders starting from one piece or one roll. Furthermore, most of the materials used in our load securing band products are "Made in Japan," ensuring high quality and stable supply by using carefully selected materials manufactured domestically. Additionally, through the manufacturing and sales of load securing bands, we promote the SDGs "12 Responsible Consumption and Production" and "13 Climate Action," aiming to secure sustainable production and consumption patterns. Our goal is to significantly reduce waste generation through prevention, reduction, recycling, and reuse. As a manufacturer's agent, we also offer a wide range of packaging materials and equipment, such as packaging tape and cushioning materials, to solve any issues you may encounter in your packaging and shipping operations.

![[Demo units available for loan] Call mat that is easy to install at a low cost *Looking for agents](https://image.mono.ipros.com/public/product/image/03b/2000717722/IPROS08657639687670039798.png?w=280&h=280)

![Stretch Film "Komaki" [Industry First! Optimal for ECO and Work Efficiency!]](https://image.mono.ipros.com/public/product/image/474/2000317425/IPROS17167699807860247107.jpeg?w=280&h=280)