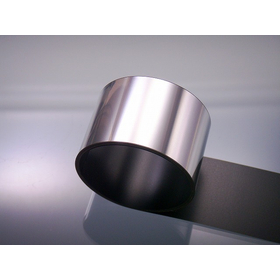

Materials for Industrial Knives and Blades [TOKUSHU KINZOKU EXCEL CO., LTD.]

TE-2, SK95, SK85, RB-S, RB-X, SUS420J2

High strength can be achieved through quenching, making our steel suitable for a variety of blades, including razor blades, cutter blades, and medical blades.

High strength can be achieved through quenching, making our steel suitable for a variety of blades, including razor blades, cutter blades, and medical blades. We control the grain size using our proprietary rolling and heat treatment technologies, which enhance hardenability, workability for blade attachment, and wear resistance. In addition to high carbon steels, we also produce various types of stainless steels, allowing you to select the most suitable steel grade based on your specific applications and required properties.

Inquire About This Product

basic information

<Manufacturing Range> Thickness: 0.030 to 2.0mm *Depending on the steel type Width: 3 to 300mm *Please inquire for widths over 300mm Length: COIL or up to 2000mm For more details, please refer to the related links or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

Razor blades, electric shaver blades, cutter blades, medical scalpel blades, long blades, cutting tools, band saws, Thomson blades, pinnacle blades, various other cutting tools, doctor blades, straight rulers, spatulas, scrapers, etc. For more details, please refer to the related links or feel free to contact us.

Line up(6)

| Model number | overview |

|---|---|

| TE-2 [TOKKIN Original Product] | It is high carbon steel. |

| SK95(SK4) | It is high carbon steel. |

| SK85(SK5) | It is high carbon steel. |

| RB-S [TOKKIN Original Product] | It is martensitic stainless steel. |

| RB-X [TOKKIN Original Product] | It is martensitic stainless steel. |

| SUS420J2 | It is martensitic stainless steel. |

catalog(1)

Download All CatalogsCompany information

TOKKIN's materials are everywhere around you, even though you can't see them! TOKKIN is a precision metal materials manufacturer founded in 1940. We produce high-quality, high-value-added materials according to the each customer specifications, such as processing metals into thin strips or sheets by cold rolling to improve mechanical properties, cladding different materials to form a single material, and applying resin or solder to metal surfaces. Our materials are used in a wide range of products, from daily life gadgets such as smart devices, PCs, automobiles, and game consoles to industrial equipment such as semiconductor manufacturing equipment, medical equipment, and textile machinery. Although our material is mostly invisible, it plays an indispensable role in ensuring that the products and their supporting components function well. High-functional materials, made possible only by TOKKIN, support the technologies that are created one after another behind the scenes.

![Product lineup [TOKUSHU KINZOKU EXCEL CO., LTD.]](https://image.mono.ipros.com/public/catalog/image/678369/IPROS12636699130436364053.jpeg?w=120&h=170)

![High corrosion-resistant and heat-resistant alloy [Special Metal Excel]](https://image.mono.ipros.com/public/product/image/ed4/2000551697/IPROS45985974740901694057.jpeg?w=280&h=280)

![Materials for Bellows [TOKUSHU KINZOKU EXCEL CO., LTD.]](https://image.mono.ipros.com/public/product/image/b61/2001431721/IPROS4932987891568662263.jpg?w=280&h=280)