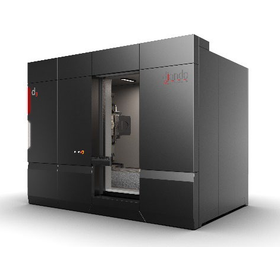

A micro-focus X-ray CT system equipped with a compact design weighing 1.3 tons and a large 417 mm flat panel detector.

■ Tube voltage 150kV, tube current 500μA high-output micro-focus X-ray tube The sealed micro-focus X-ray tube requires no maintenance and delivers sufficient power to detect fine details even in high-density metal bodies. It enables scanning of a wide range of samples, from plastics and organic materials to composite materials and lightweight alloys. ■ Large 417 mm high-resolution flat panel detector With a resolution of 3K and a large flat panel detector size of 417 x 417 mm, it delivers class-leading performance. ■ Motor-driven axis Equipped with a compact design and a full-fledged manipulator featuring zoom and height axes, it allows for convenient imaging of various subjects at the highest resolution.

Inquire About This Product

basic information

■X-ray Tube - Sealed Microfocus X-ray Tube (Maintenance-free) - X-ray Tube Voltage: 150 kV - X-ray Tube Current: 500 μA ■Detector - Flat Panel Detector - Size: 417 x 417 mm - Pixel Pitch: 139 μm ■Other Specifications - Resolution: ≤ 10 [μm] - Maximum Scan Size: Ø 270 x H 200 mm or more - Maximum Sample Weight: 5 kg - Equipment Size: L 1,260 x W 870 x H 1,640 mm - Equipment Weight: 1.3 t

Price range

Delivery Time

Applications/Examples of results

➤ Metal Parts / Additive Manufacturing Quality control of additive manufacturing parts plays an important role, as high safety standards are often required in the automotive and aerospace fields despite weight reduction. High-density aluminum parts and small metal components, such as additively manufactured aluminum samples, can be reliably inspected. ➤ Battery Inspection The unique combination of high-precision micro-focus X-ray tubes and high-resolution flat panel detectors will revolutionize the growing battery market. The high-resolution EVO 05 CT system can also observe small foreign objects and low-contrast materials. ➤ Organic Materials ➤ Plastics ➤ Electronic Components ➤ Composites ➤ Light Alloys

catalog(1)

Download All CatalogsCompany information

The history of Iris Co., Ltd. began in 1859 (the 6th year of the Ansei era) in Nagasaki's Dejima. A unique foreign trading company, which had customers such as Yukichi Fukuzawa who purchased dictionaries and various domains during the late Edo period, contributed to Japan's modernization and manufacturing by continuously introducing innovative technologies from abroad, eventually developing into the Iris Group. After relocating its headquarters to Hamburg, Germany, in 1898, the Iris Group has continued to operate under the management of the Iris family, spanning five generations of founding members, maintaining an unwavering frontier spirit as a bridge connecting global technology suppliers, primarily focusing on the Asian market. Iris Co., Ltd. remains a key hub of the Iris Group, handling a wide range of technical products and services across various fields, including printing, paper processing, automotive, aerospace, food, rubber processing, X-ray imaging and X-ray CT (Visiconsult and diondo), as well as quality assurance systems and technical materials. The company introduces cutting-edge overseas machine tools and technologies to Japan and specializes in providing project management for corporate users.

![[UHS_X-ray CT System Imaging Example] CT Cross-Section of Smartphone-Mounted CPU](https://image.mono.ipros.com/public/product/image/f39/2000971809/IPROS05749965432357988058.jpeg?w=280&h=280)

![[UHS_X-ray CT System Imaging Example] Smart Watch](https://image.mono.ipros.com/public/product/image/2092372/IPROS12859896968334187693.jpg?w=280&h=280)