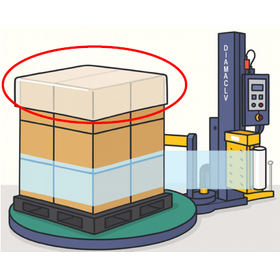

Presentation of Packaging Case Studies: Improving the Labor Shortage of the 2025 Problem with Cardboard Packaging!

Addressing the labor shortage issue that will arise in the near future in a super-aged society through packaging improvements! We are currently offering a collection of case studies on packaging improvements that have achieved reductions in workforce and shortened work hours.

The 2025 problem refers to the issue of labor shortages due to demographic changes in the population. The baby boomer generation will all be 75 years or older, resulting in approximately 21.8 million people, or 17.8% of the total population, being 75 years or older. This raises concerns about the inability to perform tasks that require multiple people and the succession issues of tasks that have been personalized by craftsmen. There will also be a competition for new graduates and other workers. Our company has a proven track record of improving work efficiency through packaging innovations using cardboard. We have contributed to society in the packaging field by transforming tasks that only craftsmen could perform into specifications that anyone can do, and enabling work to be done with fewer personnel. [Examples of Packaging Improvements (Excerpt)] - Elimination of personalization - Reduction of work hours - Reduction of workforce - Shortening of work time, etc. We are currently offering a total of eight case studies that demonstrate how packaging improvements have reduced work hours and addressed labor shortage issues. For more details, please download the PDF or feel free to contact us.

Inquire About This Product

basic information

Naviace Co., Ltd. is a reinforced cardboard manufacturer specializing in packaging design for automotive parts, metal and chemical materials, and precision instruments. ■ What does Naviace's "carbon neutral proposal" entail? 1. Cardboard has a low CO2 emission as a material, and switching from wood, plastic, and metal packaging can reduce CO2 emissions. 2. Cardboard is a material with high design flexibility, allowing for improvements in transportation efficiency, such as compact packaging, which can further reduce CO2 emissions. 3. Based on the above, by reviewing packaging design and improving material substitution and transportation efficiency, we contribute to reducing our customers' CO2 emissions. ■ Towards realizing Naviace's "carbon neutral proposal" 1. Reinforced cardboard "Naviace" boasting over 160% strength compared to conventional products. 2. "Navi Palette," with cumulative sales of 25 million units. 3. Numerous awards in packaging design contests showcasing our packaging design technical skills. → We will leverage our strengths to realize the "carbon neutral proposal." We have a wealth of experience not only with manufacturers already implementing initiatives to reduce environmental impact but also with material manufacturers in sectors like steel, non-ferrous metals, and chemicals, which are often considered challenging to address. Please feel free to contact us.

Price information

Prices vary depending on specifications, lot, and delivery conditions. Please feel free to contact us.

Delivery Time

Applications/Examples of results

■Awards in the Japan Packaging Contest / Organized by the Japan Packaging Technology Association ※Some parts omitted 2023: Chairman's Award from the Japan External Trade Organization (JETRO) "Achieved Significant Increase in Load Capacity! Cardboard Bandless Container" 2021: Large and Heavy Goods Packaging Division Award "Consolidated Packaging for Parts Transferred Between Factories" 2020: Large and Heavy Goods Packaging Division Award "Complete Cardboard Packaging for Self-Propelled RC Sprayers" 2019: Logistics Award "Complete Cardboard Packaging for Gear Grinding Wheels" 2019: Award from the Director of the Manufacturing Industries Bureau, Ministry of Economy, Trade and Industry "Complete Cardboard Conversion from Wooden Frame Packaging" 2018: Logistics Award "Development of Slip Master" 2018: Large and Heavy Goods Packaging Division Award "Suspended Packaging for Roll Products" 2017: Logistics Award "Suspended Packaging for Rolls" 2016: Division Award "Complete Cardboard Packaging for Aircraft Seats" 2011: Chairman's Award from the Japan Chamber of Commerce and Industry "Complete Cardboard Packaging for Large Copiers" 2009: Minister of Economy, Trade and Industry Award (Highest Honor) "Packaging of 40 Chairs for Export"

catalog(2)

Download All CatalogsNews about this product(1)

Company information

Naviace Co., Ltd. celebrated its 70th anniversary in January 2025. In August 2023, the group company "Naviace Kanto Co., Ltd." completed a new factory in Itakura Town, Ora District, Gunma Prefecture (10 minutes from the "Tatebayashi IC" on the Tohoku Expressway). The facility has expanded its production capabilities for reinforced cardboard "Naviace" and cardboard pallets "Navi Palette" and has relocated. This strengthens the supply capacity from the Kanto region to the Tohoku region, establishing a more unified sales and production system within the group. ■ Business Overview Manufacturing and sales of reinforced cardboard "Naviace/Naviace Plus" and cardboard pallets "Navi Palette." Using these materials, we are working with our customers to streamline logistics across various industries, from automotive parts and machinery to electronics, chemicals, and food sectors. ■ Company Overview Company Name: Naviace Co., Ltd. (Formerly Nakatsugawa Packaging Industry Co., Ltd.) Capital: 100 million yen ■ Locations Headquarters: Kasugai City, Aichi Prefecture Nakatsugawa Factory/Sales Office: Nakatsugawa City, Gifu Prefecture Kameyama Factory/Sales Office: Kameyama City, Mie Prefecture Kakegawa Factory/Sales Office: Kakegawa City, Shizuoka Prefecture Kanagawa Sales Office: Atsugi City, Kanagawa Prefecture Naviace Kanto: Itakura Town, Ora District, Gunma Prefecture

![[Improvement Case] Reduction of air freight and logistics costs (conversion of wooden boxes to all cardboard)](https://image.mono.ipros.com/public/product/image/1d6/2000683818/IPROS03121308562452132173.jpeg?w=280&h=280)

![[Pallet Management System] Data management with QR codes and terminals / Prevents loss!](https://image.mono.ipros.com/public/product/image/6c3/2000702555/IPROS09922554958312466508.jpeg?w=280&h=280)

![[Pallet Management System] Prevents Loss and Supports Maintenance Inspections](https://image.mono.ipros.com/public/product/image/9ac/2001530998/IPROS6194396489798150168.jpg?w=280&h=280)