Think about cost reduction in the long term! From an era of disposables to a value of continued use.

The reusable anti-collapse bands, compared to conventional stretch film, will definitely increase the initial costs of the anti-collapse band products. However, please calculate the following amounts for one month, six months, one year, three years, etc.: - Purchase cost of stretch film - Disposal costs after use - Labor time required for stretch film wrapping While our anti-collapse band products have a high initial cost, once you become accustomed to the work, the labor time can be significantly reduced compared to that of stretch film. Most importantly, since they are reusable, disposal costs can be greatly reduced. Our products are made using carefully selected materials and are manufactured by skilled artisans in Japan. As a result, most of our customers have been using them for over five years (up to a maximum of 15 years). (This varies depending on the customer's usage environment.) Due to their long lifespan, repeat purchases from our company take time (sadly), but our customers are very pleased with them.

Inquire About This Product

basic information

【Material】 PP, Nylon 【Size】 Various sizes depending on the product For sizes other than standard products, we can accommodate custom orders starting from one piece. Please feel free to contact us. There are cheaper similar products available, but the durability of the materials is different. Please consider not only the initial cost but also the long-term perspective.

Price range

Delivery Time

Applications/Examples of results

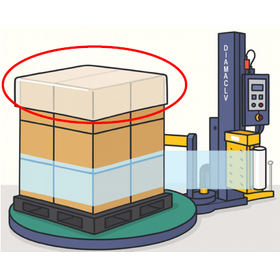

Cargo, prevention of cargo collapse in the warehouse Effects expected beyond cost reduction: - Simplified management of the band itself (reduction of burdens such as inventory management of stretch film and storage locations) - Improved work efficiency (time savings in wrapping work, approximately reduced to 1/3) - Enhanced safety (elimination of the need for cutters or scissors when cutting film, reducing the risk of cuts) - High evaluation from business partners and suppliers as a sustainable initiative

Detailed information

-

[Adoption Results] A certain manufacturing company is promoting efforts to solve environmental issues by reducing film usage through the combined use of stretch film.

-

[Adoption Results] Nakahaya Chemical Industry Co., Ltd. The stretch film used between the manufacturing plant and the warehouse was changed to our "Cargo Logister." As a result, it was evaluated that this led to significant cost reductions.

catalog(4)

Download All Catalogs

Company information

Our company's load securing band products were launched in 1990, pioneering the industry, and have been well-loved for many years. We now offer a wide variety of options, replacing traditional stretch film used for load securing with reusable bands, contributing to cost reduction, improved work efficiency, and addressing environmental issues by reducing plastic waste. For requests beyond standard products, we can accommodate custom orders starting from one piece or one roll. Furthermore, most of the materials used in our load securing band products are "Made in Japan," ensuring high quality and stable supply by using carefully selected materials manufactured domestically. Additionally, through the manufacturing and sales of load securing bands, we promote the SDGs "12 Responsible Consumption and Production" and "13 Climate Action," aiming to secure sustainable production and consumption patterns. Our goal is to significantly reduce waste generation through prevention, reduction, recycling, and reuse. As a manufacturer's agent, we also offer a wide range of packaging materials and equipment, such as packaging tape and cushioning materials, to solve any issues you may encounter in your packaging and shipping operations.

![[Packaging Material] Eco-friendly load securing band "Palemaki" GX promotion cost reduction](https://image.mono.ipros.com/public/catalog/image/01/746/657714/IPROS73109364080407149030.jpeg?w=120&h=170)

![[Packaging Material] Cart-Specific Load Securing Band 'Dolly Maki'](https://image.mono.ipros.com/public/catalog/image/01/d95/731106/IPROS17148797282185424665.jpeg?w=120&h=170)

![Stretch Film "Komaki" [Industry First! Optimal for ECO and Work Efficiency!]](https://image.mono.ipros.com/public/product/image/474/2000317425/IPROS17167699807860247107.jpeg?w=280&h=280)