The structure has been made easy for on-site installation and relocation is also possible! It is designed specifically for large cuts, compact, and does not require foundation work.

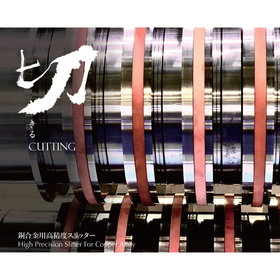

Here is an introduction to a case study on the production of a "large sheet slitter line for thick plates." It is designed specifically for large sheets, making it compact and eliminating the need for foundation work. It features a common base structure and includes a loop table. As a result, it has become easy to install on-site and can also be relocated. Please feel free to contact us if you have any inquiries. 【Case Overview】 ■Challenges - Designed specifically for large sheets, compact, and eliminates the need for foundation work. ■Effects and Results - It has become easy to install on-site and can also be relocated. *For more details, please download the PDF or feel free to contact us.

Inquire About This Product

basic information

【Solution】 ■ Establish a common base structure and set up a loop table *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Our company is primarily a manufacturer of metal production equipment, focusing on copper and copper alloys. We also engage in contract manufacturing of metal-resin bonding lines for European factories by major domestic composite material manufacturers, as well as the design, manufacturing, and sales of research and development equipment for universities and research institutions, and industrial automation equipment. Additionally, we develop industrial software such as remote monitoring systems, and we also conduct prototype development, design, and manufacturing of roll levelers for various materials. Please feel free to contact us if you have any requests.

![[Production Example] B-Cut Slitter Line](https://image.mono.ipros.com/public/product/image/3b4/2001537663/IPROS5450479659327987530.jpg?w=280&h=280)

![[Production Example] Single Loop Slitter Line](https://image.mono.ipros.com/public/product/image/428/2001537660/IPROS17328457435278907037.png?w=280&h=280)