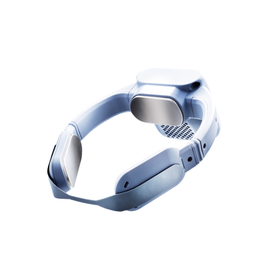

Mobile cooling shelter (windbreak room) for railway inspection, environmental improvement.

UNICOM COOL

Mobile cooling shelter for outdoor installation to prevent heatstroke for railway inspection workers.

In the railway industry, inspection work often takes place outdoors, making heatstroke prevention during the summer a significant issue. In particular, inspections of tracks and vehicles are frequently conducted under the blazing sun, making the health management of workers essential. Heatstroke poses risks that can lead to decreased work efficiency and serious accidents. Our mobile cooling shelters have been developed to create a comfortable outdoor working environment and protect the health of workers. 【Usage Scenarios】 - Track inspection work - Vehicle inspection work - Work within train stations - Other general outdoor inspection tasks 【Benefits of Implementation】 - Reduction of heatstroke risks - Improvement in work efficiency - Health management of workers - Enhanced safety

Inquire About This Product

basic information

【Features】 - Compact design for easy mobility - Easy installation by two people in 20-30 minutes - Disassemblable and storable for space-saving - Optional installation of spot air conditioning available - Usable comfortably throughout the year 【Our Strengths】 Kawakami Sangyo Co., Ltd. has supported safe and efficient logistics through the manufacturing and sales of packaging materials. This product also leverages our years of experience and technology to meet our customers' needs.

Price information

Open price *The product price does not include the spot cooler.

Price range

P5

Delivery Time

Applications/Examples of results

【Installation Locations】 Construction sites, factories, outdoor events, sports events, public facilities, leisure facilities, disaster sites 【Uses】 Heat prevention and heatstroke measures, rest areas, improvement of work environment and workplace environment

catalog(3)

Download All Catalogs

Company information

Kawakami Sangyo Co., Ltd. is a manufacturer of packaging materials centered on the production and sale of bubble sheet "Puchi Puchi(R)." Since its founding in 1968, it has continued to provide products that support safe and efficient logistics. In addition to using over 90% recycled materials in Puchi Puchi (average across all factories for the fiscal year 2023), the company is also focusing on the use of biodegradable and biomass materials, leading the industry as a top manufacturer. Moreover, in addition to bubble sheet, it is committed to developing environmentally friendly products such as plastic cardboard "Eko Real Board" and "Plapaal" that utilize recycled materials. The company also supports the introduction of automatic packaging machines like "Puchi Packer," aiding in the efficiency of on-site operations. In addition to packaging, it has developed and sold the cute "Heart Grain Puchi Puchi," catering to a wide range of fields including art and gifts. In 2021, to aim for zero plastic waste, the company officially launched the "Puchi Puchi Recycling Project," working on plastic recycling and contributing to the realization of a comfortable and sustainable society. Not limited to packaging materials, it sells various products such as partitions, plastic beds, and storage batteries.

![[Data] Hatena Magazine Precision Air Conditioning Equipment Edition / Apiste](https://image.mono.ipros.com/public/product/image/b54/2000625526/IPROS05591133991259215425.jpeg?w=280&h=280)