For precision processing of rubber, sponge, and plastic interior parts. Cutting and punching with a width of 0.1mm.

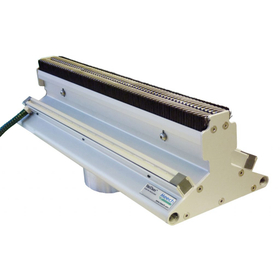

In the manufacturing of automotive interior parts, it is important to balance design and functionality. Particularly in the processing of rubber and sponge components that affect the comfort and safety of the interior, high precision and the ability to accommodate diverse shapes are required. Complex shapes and fine processing that are difficult with conventional methods can be achieved with water jet cutting. Our water jet processing uses a 0.1mm width nozzle for cutting and piercing, enhancing the design freedom of interior parts. 【Application Scenes】 - Dashboard components - Door trim components - Seat components - Weather strips 【Benefits of Implementation】 - Enables the manufacturing of complex-shaped parts - Cost reduction through mold-less production - Shortened prototyping period - Compatibility with various materials

Inquire About This Product

Related Videos

basic information

【Features】 - High-precision processing with a 0.1mm width nozzle - Compatible with various materials such as rubber, sponge, and plastic - No need for molds, reducing initial costs - Capable of handling complex shapes and fine processing - Shapes that do not have blade radii at cut-out sections are also possible 【Our Strengths】 Daiichi Shoko is based in Nagano Prefecture and engages in contract processing and sales of industrial functional and mechanical parts made from various materials. Centered around our own manufacturing plant, we provide a wide range of products and services related to "monozukuri" (manufacturing) across diverse industrial sectors. We propose optimal processing methods tailored to our customers' needs and deliver high-quality products.

Price range

Delivery Time

Applications/Examples of results

■Packing ■Buffer material

catalog(2)

Download All CatalogsCompany information

Daiichi Shoko Co., Ltd. is based in Nagano Prefecture and engages in the contract processing and sales of industrial functional and mechanical parts made from various materials. Centered around its own manufacturing plant, the company utilizes plastics, metals, rubber, films, sponges, inorganic materials, and composite materials to provide a wide range of products and services related to "monozukuri" (manufacturing) across diverse industrial sectors. Furthermore, it offers specialized units and equipment products assembled from functional parts made of resins and metals, achieving high cost performance. As a trusted partner, we assist our customers in making further leaps into new and advanced fields they aim to pursue.

![[Example] Shoe Water Jet Cutting](https://image.mono.ipros.com/public/product/image/1b3/2000851802/IPROS68882901469221903141.png?w=280&h=280)