Achieving insulation through precision processing of materials such as rubber, sponge, and cork.

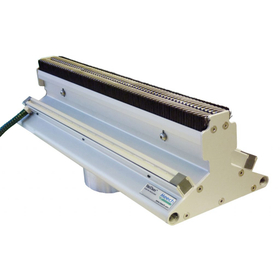

In the energy industry, precise processing of insulating materials is required to ensure the safety of electrical equipment. Particularly in high-voltage environments, even slight gaps or shape defects that compromise insulation performance can lead to serious accidents. Water jet cutting can precisely cut and shape materials such as rubber and sponge with a 0.1mm wide nozzle, allowing for the realization of shapes that maximize insulation performance. 【Application Scenes】 - Electrical insulation components - Gaskets - Sealing materials 【Benefits of Implementation】 - Improved insulation performance through precise shape processing - Compatibility with a variety of materials - Flexible response from prototyping to mass production

Inquire About This Product

Related Videos

basic information

【Features】 - Precision processing with a 0.1mm width nozzle - Compatible with various materials such as rubber, sponge, and cork - Achieves shapes that are difficult with press processing or plotter processing - Capable of creating shapes without blade rounding - Plastic cutting processing is also possible depending on the material and thickness 【Our Strengths】 Daiichi Shoko is based in Nagano Prefecture and engages in contract processing and sales of industrial functional and mechanical parts made from various materials. Centered around our own manufacturing plant, we provide a wide range of products and services related to diverse "monozukuri" (manufacturing) across various industrial sectors. We aim to assist our customers in achieving further leaps in new and advanced fields as a trusted partner.

Price range

Delivery Time

Applications/Examples of results

■Packing ■Buffer material

catalog(2)

Download All CatalogsCompany information

Daiichi Shoko Co., Ltd. is based in Nagano Prefecture and engages in the contract processing and sales of industrial functional and mechanical parts made from various materials. Centered around its own manufacturing plant, the company utilizes plastics, metals, rubber, films, sponges, inorganic materials, and composite materials to provide a wide range of products and services related to "monozukuri" (manufacturing) across diverse industrial sectors. Furthermore, it offers specialized units and equipment products assembled from functional parts made of resins and metals, achieving high cost performance. As a trusted partner, we assist our customers in making further leaps into new and advanced fields they aim to pursue.

![Case Studies of Processing - Machine Parts Edition Part 2 - [From Mass Production to Prototype Processing]](https://image.mono.ipros.com/public/product/image/605/2001488868/IPROS14401427055884021076.jpg?w=280&h=280)

![[Case Study of Solution Proposal] Solved issues related to thermal effects while processing test specimens!](https://image.mono.ipros.com/public/product/image/df7/2001490596/IPROS8526685682438222836.png?w=280&h=280)