Opening the world of nanotechnology! Contact angle measurement with micro droplets and multi-faceted analysis enable control of wettability in the nanoscale domain.

Patterns etched onto wafers and glass substrates are becoming finer. The automatic micro contact angle meter (MCA) is gaining attention as the next surface evaluation device in the field of micromachines/MEMS.

Inquire About This Product

basic information

MCA-4 Create micro droplets and measure the contact angle on fine surfaces. ● Specify measurement points while confirming the actual object ● Create micro droplets in the picoliter order ● Measure contact angles on ultra-fine surfaces within 100μm MCA-J2 Directly observe droplets ejected from the inkjet head and measure the contact angle. ● Quantitatively eject droplets of dispersions/viscous liquids, etc. ● Evaluate wettability after droplet impact

Price information

-

Delivery Time

Applications/Examples of results

●Surface evaluation on fine patterns such as wafer glass substrates ●Evaluation of hydrophilicity and hydrophobicity of single fibers and hair ●Permeability evaluation through measurement of paper cross-sections ●Wettability evaluation of inkjet inks with media and materials such as films and paper ●Wettability evaluation of conductive and insulating inks with circuit boards and materials ●Wettability evaluation of RGB inks with color filter substrates

catalog(1)

Download All CatalogsNews about this product(2)

Company information

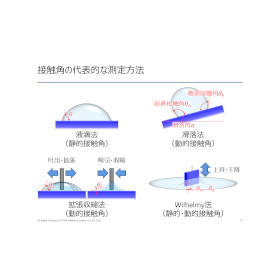

Our contact angle meters and surface tension meters have a wealth of delivery records and publications. We also provide equipment related to interfaces, such as friction meters, zeta potential meters, adhesive film peeling analysis devices, and LB film production devices, contributing multifacetedly to our customers' research, development, and quality control. ★ We accept commissioned measurements. Our commissioned measurements utilize high-performance equipment, and dedicated measurement personnel handle everything from measurement to reporting. We strive to provide reliable data that serves as evaluation criteria for material assessment. - Static/Dynamic/Contact Angle (wetting properties, liquid repellency, cleaning evaluation, surface free energy analysis) - Static/Dynamic Surface and Interfacial Tension (permeability, emulsification, solubility, wettability, foaming) - Lamella Length (foam stability, coating pickup, liquid drainage, wicking evaluation) - Powder Wettability (wettability of powders, wettability due to surface treatment and roughness of powders, wettability evaluation based on powder penetration speed) - Static/Dynamic Friction Wear Analysis (friction wear, lubricity, stickiness, slip properties) - Tensile Testing (adhesion, angle dependence, light peeling, high-speed peeling) - Zeta Potential (particle size distribution, dispersion stability, aggregation, sedimentation) - Anti-fogging Evaluation (degree of fogging, transparency, condensation)