Easily measure the contact angle of large substrates and actual samples on-site!

Simple, lightweight, and compact! A portable contact angle meter perfect for large substrates and actual measurements! Easy-to-use handheld type!

Inquire About This Product

basic information

【Features】 ○ Measurement is easy to operate with a single button. Work can be carried out smoothly. ○ Liquid sample replacement is simple and can be done by just swapping syringes. ○ Time-lapse measurements can be performed with image capture at a rate of 30 images per second. ○ Surface tension measurement and surface free energy analysis using the pendant drop method are also possible. ○ Measurements can be conducted while confirming the droplet's dropping point. ● For more details, please contact us.

Price information

-

Delivery Time

Applications/Examples of results

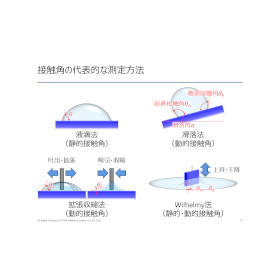

Contact angle measurement

catalog(1)

Download All CatalogsNews about this product(3)

Company information

Our contact angle meters and surface tension meters have a wealth of delivery records and publications. We also provide equipment related to interfaces, such as friction meters, zeta potential meters, adhesive film peeling analysis devices, and LB film production devices, contributing multifacetedly to our customers' research, development, and quality control. ★ We accept commissioned measurements. Our commissioned measurements utilize high-performance equipment, and dedicated measurement personnel handle everything from measurement to reporting. We strive to provide reliable data that serves as evaluation criteria for material assessment. - Static/Dynamic/Contact Angle (wetting properties, liquid repellency, cleaning evaluation, surface free energy analysis) - Static/Dynamic Surface and Interfacial Tension (permeability, emulsification, solubility, wettability, foaming) - Lamella Length (foam stability, coating pickup, liquid drainage, wicking evaluation) - Powder Wettability (wettability of powders, wettability due to surface treatment and roughness of powders, wettability evaluation based on powder penetration speed) - Static/Dynamic Friction Wear Analysis (friction wear, lubricity, stickiness, slip properties) - Tensile Testing (adhesion, angle dependence, light peeling, high-speed peeling) - Zeta Potential (particle size distribution, dispersion stability, aggregation, sedimentation) - Anti-fogging Evaluation (degree of fogging, transparency, condensation)

![透明PCA[1].jpg](https://image.mono.ipros.com/public/product/image/f82/2491010/IPROS10915349137429590621.jpg?w=280&h=280)

![[For the pharmaceutical manufacturing industry] Digitizing entry management in oxygen-deficient hazardous work.](https://image.mono.ipros.com/public/product/image/20a/2001525768/IPROS14827379347403299223.jpg?w=280&h=280)

![[Video] Useful Video on Electrical Conductivity Measurement (Desktop Electrical Conductivity Meter)](https://image.mono.ipros.com/public/product/image/59289/IPROS12986349931594449331.png?w=280&h=280)