Evaluate the surface treatment state of various powders such as fillers, pigments, and food-grade powders based on their wettability and permeability with solvents. Address the issues of powder contact angle measurement and "filling methods."

Powder is a collection of finely crushed solids and possesses unique properties that differ from the three states of matter: solid, liquid, and gas. This leads to various challenges in research and development as well as in production environments. Today, powders have become essential in a wide range of fields, from pharmaceuticals, food, and cosmetics to advanced industries such as paints, batteries, and nanotechnology. While the use of powders and processed products is generally in the form of tablets or dispersions, in order for them to fulfill their roles as products, the penetration of liquids and wettability are important factors in almost all cases, regardless of the form. The measurement of liquid penetration speed and contact angles in powders is an old yet new technology, and by utilizing the latest know-how, it is possible to obtain reproducible data.

Inquire About This Product

basic information

【Features】 ○ By displaying measurement values and graphs simultaneously, data can be visually evaluated. ○ The powder compactor allows for consistent adjustment of porosity. ○ The powder filling column suppresses wetting penetration of the column itself depending on the material. ○ The material at the tip of the powder filling column reduces the variation in contact penetration speed at the liquid contact area. ○ It has high expandability, allowing for various measurements by adding optional sensors and analysis software. ● For other functions and details, please download the catalog or contact us.

Price information

-

Delivery Time

Applications/Examples of results

For other features and details, please download the catalog or contact us.

catalog(2)

Download All CatalogsNews about this product(2)

Company information

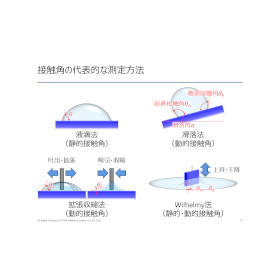

Our contact angle meters and surface tension meters have a wealth of delivery records and publications. We also provide equipment related to interfaces, such as friction meters, zeta potential meters, adhesive film peeling analysis devices, and LB film production devices, contributing multifacetedly to our customers' research, development, and quality control. ★ We accept commissioned measurements. Our commissioned measurements utilize high-performance equipment, and dedicated measurement personnel handle everything from measurement to reporting. We strive to provide reliable data that serves as evaluation criteria for material assessment. - Static/Dynamic/Contact Angle (wetting properties, liquid repellency, cleaning evaluation, surface free energy analysis) - Static/Dynamic Surface and Interfacial Tension (permeability, emulsification, solubility, wettability, foaming) - Lamella Length (foam stability, coating pickup, liquid drainage, wicking evaluation) - Powder Wettability (wettability of powders, wettability due to surface treatment and roughness of powders, wettability evaluation based on powder penetration speed) - Static/Dynamic Friction Wear Analysis (friction wear, lubricity, stickiness, slip properties) - Tensile Testing (adhesion, angle dependence, light peeling, high-speed peeling) - Zeta Potential (particle size distribution, dispersion stability, aggregation, sedimentation) - Anti-fogging Evaluation (degree of fogging, transparency, condensation)