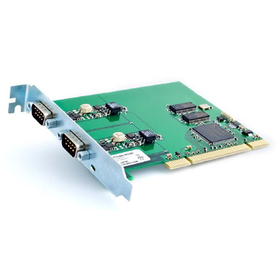

Camera Link Image Input Board HST Pleiad CL4e

This is an image input board that connects four Camera Link cameras and achieves high-speed, stable image acquisition. ⧉ Features of the Image Input Board HST Pleiad CL4e ⧉ ○ Independent 4-channel simultaneous acquisition With independent 4-channel input from four cameras in the Base Configuration, asynchronous simultaneous acquisition is possible. ○ PCI Express (x4) bus support The PCI Express (x4) bus support allows for high-speed transfer of high-resolution images. ○ High-speed image transfer and memory access With independent 4-channel direct memory access (DMA), pipeline processing, and onboard FIFO memory, parallel operation of image acquisition and transfer processing is achieved, enabling optimal high-speed image transfer for vision applications. ○ Camera compatibility Supports area scan and line scan cameras, as well as color and monochrome cameras. ○ Compatible with PoCL (Power Over Camera Link)

Inquire About This Product

basic information

⧉ HST Pleiad CL4e Specifications ⧉ ○ Physical Specifications ・Two-board configuration: main board and sub-board ・x4 Standard height ・Half length card (111.15mm × 167.65mm) ・4 x SDR mini connectors ○ Memory ・512MB FIFO ○ Video Input ・Supports up to 85MHz for 4 Base Configuration Camera Link cameras per input ○ PC Memory Access ・4 independent DMA channels ・Direct Memory Access (DMA) to PC memory concurrent with image capture ○ Parallel I/O ・16 General Purpose I/O ・4 Trigger lines, 4 Strobe lines ・24-bit position coefficient counter, encoder

Price information

Prices vary depending on the quantity. Please inquire separately.

Delivery Time

※Please inquire separately about the delivery date.

Applications/Examples of results

For more details, please contact us.

catalog(1)

Download All CatalogsCompany information

Our company is a machine vision manufacturer specializing in the development, manufacturing, and sales of image processing software and systems for various manufacturing and inspection equipment manufacturers in the semiconductor, electronics, and pharmaceutical industries. In manufacturing sites around the world, image processing has become one of the essential core technologies for cost reduction, quality improvement, and increased production efficiency. In particular, we have extensive experience and achievements in positioning, barcode and character reading, measurement, and inspection applications. For the pharmaceutical industry, we focus on utilizing highly reliable ID reading technology, as well as inspecting the printed quality of characters, GS1-DataBar barcode reading, and character and barcode printing.