The table height is 70cm, providing good workability! With a tie bar-less design, the workspace is spacious, and robot integration is easy.

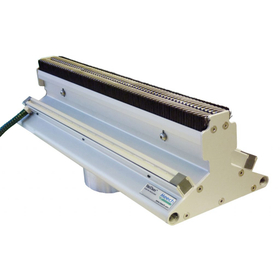

The "VNT-100R/HS" is a vertical (upright) injection molding machine with a tie-bar-less structure and an L-shaped frame design, making it easy to coordinate with robots in a spacious work area. Its improved operability, based on the principle of being "user-friendly," is a key feature. The low table position is expected to enhance efficiency and safety during mold exchange operations. Additionally, the electric servo table enables high-speed rotation and high-precision stopping. 【Features】 ■ Compact design with a maximum installation size of 2.72×1.6m ■ Tie-bar-less clamping method ■ Improved efficiency for insert and hoop molding ■ 20% reduction in power consumption compared to conventional hybrid machines (compared to our products) *You can view materials such as the comprehensive catalog from the "PDF Download" section. For more details, please refer to the materials or feel free to contact us.

Inquire About This Product

basic information

【Specifications】 Hybrid Screw diameter (mm): Φ34-Φ38 Theoretical injection volume (cm3): 136-170 Maximum mold dimensions (mm): 450×450 Tie-bar-less system Clamping method: Direct pressure type Table height (mm): 700 Maximum height: 3.2m Transport height: 2.53m Machine weight: 8.2t *You can view materials such as the comprehensive catalog by downloading the PDF. For more details, please refer to the materials or feel free to contact us.

Price information

-

Delivery Time

Applications/Examples of results

For more details, please contact us.

catalog(3)

Download All CatalogsCompany information

Since our establishment in 1959, we have been dedicated to the manufacturing and sales of plastic injection molding machines. During this time, plastic has contributed to and continued to develop in various industries, becoming an essential basic material comparable to iron and others. In the future, it will be necessary to produce molded products with even higher precision, which will require increasingly advanced cutting-edge technology. At Hishiya, we aim to meet our users' expectations by creating products that establish "energy efficiency," "space-saving," and "high speed," striving to be a company that can contribute to higher quality and environmental issues.

![[Information] Achieving work efficiency with a non-tie bar 'Vertical Injection Molding Machine'](https://image.mono.ipros.com/public/catalog/image/01/589/333541/IPROS20495803332860064711.jpeg?w=120&h=170)