Revolutionary stable measurement at ultra-high temperatures.

- Measurement error is within ±5mm even at ultra-high temperature molten metal of 1800℃. - The measurement cycle can be set from a minimum of 1ms. - It is possible to save images while viewing the target object with a camera and simultaneously file the level data. - Innovative software techniques can absorb variations and noise in the measurement target, allowing for optimal operations such as weighted averages over a certain time and output of minimum values. - No special operations are required for measurement distances from 500mm to 100m (recommended under 20m). - Data analysis, accumulation, and various graphing can be done on a PC.

Inquire About This Product

basic information

- Measurement error is within ±5mm even at ultra-high temperature molten metal of 1800℃. - The measurement cycle can be set from a minimum of 1ms. - It is possible to save images while viewing the target object with a camera and simultaneously file the level data. - Revolutionary software techniques can absorb fluctuations and noise in the measurement target, allowing for optimal operations such as weighted averages over a certain time and output of minimum values. - No special operations are required for measurement distances from 500mm to 100m (recommended under 20m). - Data analysis, accumulation, and various graphing can be performed on a PC.

Price information

-

Delivery Time

P4

Applications/Examples of results

- Alloy steel plant, steelmaking plant, casting line, cupola furnace top monitoring, pouring spout level monitoring - Incinerator waste level, various melting furnaces, melting furnace level, various heat treatment furnaces, distance measurement in ambient temperature range

Company information

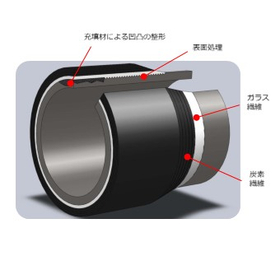

Our company was founded in 1983, coinciding with the birth of the CCD camera, which has now become commonplace and is owned by everyone. While developing application products and innovations related to CCD cameras, we have consciously brought to the world the eyes of extreme work robots. The Furnacecope, which is our registered trademark, is particularly groundbreaking in its cooling jacket structure, for which we hold a patent. This camera technology is a pioneer in Japan and has been developed through many years of effort and challenges, boasting a structure and functionality that have led to numerous inquiries from top companies across various industries, bringing us to where we are today.

![[Case Study] Radar-type Microwave Level Meter for Monitoring Hot Metal Ladle Tapping Level](https://image.mono.ipros.com/public/product/image/c44/2000439695/IPROS42940849182348455458.jpeg?w=280&h=280)

![Ultrasonic Level Meter 'LIU-330' [Corrosion-Resistant Structure!]](https://image.mono.ipros.com/public/product/image/76b/2000330989/IPROS2618679370589544408.png?w=280&h=280)

![[Basic Knowledge Material] Sealant specialized for deck repair of floating roof tanks.](https://image.mono.ipros.com/public/product/image/cb2/2000620968/IPROS52605113925775414442.png?w=280&h=280)