Idea Box for Smooth and Smart Experimentation vol. 5

Measurement of surface tension of membranes, do not misinterpret the data. Introducing approaches useful in the experimental field.

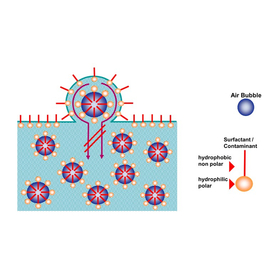

Very simple measuring devices are commercially available. This method measures surface tension and surface free energy from the contact angle of liquids. By dropping a liquid with known surface tension (such as water or cyclohexane) onto a coating or solid, the contact angle can be measured. The surface free energy (dispersive component, polar component, total) can be calculated from the contact angles of multiple liquids. *For more detailed information, please refer to the PDF document. Feel free to contact us for further inquiries.

- Company:ビックケミー・ジャパン

- Price:Other

![Solution with PFAS-free additives [BYK]](https://image.mono.ipros.com/public/product/image/2074951/IPROS4980094373547333988.jpg?w=280&h=280)

![[Information] Solutions that contribute to sustainability](https://image.mono.ipros.com/public/product/image/50b/2000889851/IPROS32182785078531588117.png?w=280&h=280)