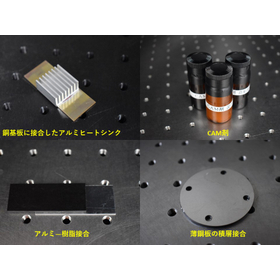

Dissimilar Material Joining Technology "CAM Joining"

Our new joining technology is environmentally friendly, easy to install, and enables cost reduction.

CAM bonding is a technology that joins two materials using two bonding mechanisms: "Chemical & Melting." It is possible to bond "metal and resin" or "different metals" using CAM agents. CAM agents are made only from materials that consider safety and a secure environment. CAM bonding reduces costs by requiring fewer processes, no special equipment, and low consumption. 【Features】 ■ Bonding is possible with a CAM layer thickness of just a few micrometers, achieving low consumption. ■ Easy handling as bonding can be done anytime after applying and drying the CAM agent. ■ A bonding layer is formed after applying and drying the CAM agent. ■ The CAM agent is a water-soluble, easy-to-use liquid type. ■ The CAM agent is made from environmentally friendly, safe materials. ■ Compatible with all metals that oxidize on the surface (aluminum, copper, steel, etc.). ■ Bonding of glass and plastic is also possible. *For more details, please refer to the PDF document or feel free to contact us.

- 企業:輝創 輝創株式会社

- 価格:Other

![[Case Study Presentation] CAM Joining Enabled Dissimilar Material Bonding with Low Thermal Resistance](https://image.mono.ipros.com/public/product/image/146/2001502278/IPROS11074528976109451525.png?w=280&h=280)