For Accommodations: 'Guardian Deity - Mold Guardian' R.C. Umehara

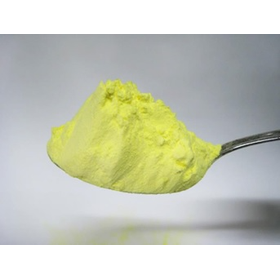

★Samples available at Daikisan Industry★ Removes mold, viruses, and bacteria! Odor elimination power that doesn't just mask smells! Disinfectant, antibacterial, and antifungal agent 'Guardian Deity'

**Features of the Guardian God** 1. Excellent sterilization, antiviral, antifungal, and deodorizing effects. 2. Low likelihood of developing resistant bacteria. 3. Extremely low corrosiveness to metals. 4. No unpleasant chlorine smell; odorless. 5. High safety recognized by public institutions; safer than salt or caffeine in terms of oral toxicity! One of the components of the Guardian God, chlorine dioxide in aqueous form "PUROGENE," is used as a sterilizing, antibacterial, deodorizing, and disinfecting agent for tap water, food processing facilities, machinery, and equipment, and is adopted as the final sanitizer for food hygiene management in the United States and many other countries, receiving high praise. Furthermore, it is the only product recognized as a disinfectant for drinking water on aircraft worldwide. In Japan, it received approval from the Ministry of Health as a disinfectant for drinking water (chlorine dioxide) in 2000. Another component, Mold Guardian, has a history of over 30 years and is an excellent antibacterial agent widely used in various fields of antibacterial and antifungal applications, including food factories, combining high effectiveness and safety. The Guardian God is a completely new disinfectant, antiviral, antibacterial, antifungal, and deodorizing agent with powerful dual action, specially formulated to maximize the synergistic effects of these two components. Free samples available! *If you would like a sample, please inquire with "Sample Request."

- Company:大喜産業

- Price:Other

![[For Medical and Care Facilities] 'Guardian Deity: Mold Guardian' R.C. Umehara](https://image.mono.ipros.com/public/product/image/bfb/2000604493/IPROS17141056517845204404.jpeg?w=280&h=280)

![Spherical phenolic resin [Good fluidity and high filling capacity] *Characteristic table available.](https://image.mono.ipros.com/public/product/image/62b/2000310086/IPROS8375492184728129058.jpg?w=280&h=280)