Logistics Use Resin Belt "LOGISTAR Series" / Mitsuboshi Belt

<Contributing to SDGs (Decarbonization and GX)> Reducing noise that can be a barrier for workers! Providing a comfortable working environment.

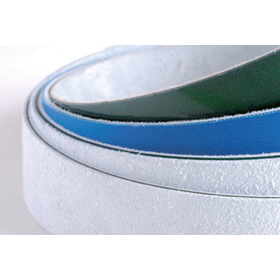

The "LOGISTAR Series" is a resin belt for logistics applications. It features a "steep incline belt" that is less slippery even when dust accumulates, and an "ultra-low noise belt" that produces minimal rubbing noise. These belts can be applied in logistics terminals, airports, and newspaper distribution centers where high-speed operations are required. 【Features】 ■ Steep Incline Belt - Less slippery even when dust accumulates - Reduces noise from the surface pattern passing through the return roller ■ Ultra-Low Noise Belt - Produces minimal rubbing noise - Uses a special canvas for the underside of the belt *For more details, please refer to the PDF materials or feel free to contact us.

- Company:カテックス 工業用品営業本部

- Price:Other