S-Style Co., Ltd. Product Handling Comprehensive Catalog

This is a product that has been repeatedly tested and completed at a construction company that actually uses it.

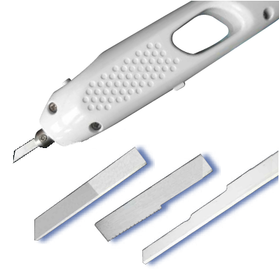

This is the "Product Handling Comprehensive Catalog" of S-Style Co., Ltd., which sells attachments for construction machinery, including the cutter blade "Ryoma Blade." It features products developed with the cooperation of scholars, engineers, and fishing experts from sunny Tosa. The products have been repeatedly tested at construction companies where they are actually used, leading to their completion. 【Contents】 ○ Material ○ Artisan ○ Technology ○ Sincerity ○ Product For more details, please contact us or download the catalog.

- Company:エス・スタイル 岡山本社

- Price:Other

![[Processing Example] Moving Blade High Hardness Parts Processing](https://image.mono.ipros.com/public/product/image/b80/2000610790/IPROS78372550931923055009.jpeg?w=280&h=280)