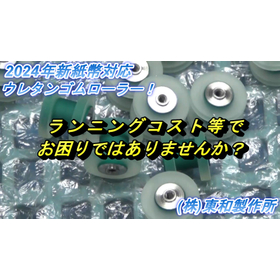

Liquid polyurethane rubber roller

Liquid polyurethane rubber rollers used in financial terminals.

It is often used in rollers for financial terminals. The raw materials are classified into ether-based and ester-based materials. Ether-based liquid urethane rubber has excellent abrasion resistance and hydrolysis resistance, available in high-strength grades (hardness A70 to 95°) and low-hardness grades (hardness A50 to 70°). Ester-based liquid urethane rubber has excellent abrasion resistance, ink resistance, and chemical resistance, available in high-strength grades (hardness A70 to 95°) and low-hardness grades (hardness A50 to 70°). *For more details, please refer to the PDF document or feel free to contact us.

- Company:東和製作所 本社

- Price:Other

![Rubber Roller [Technical Introduction and Product Catalog]](https://image.mono.ipros.com/public/product/image/719/2000463772/IPROS64199348446520257382.jpeg?w=280&h=280)

![Solving Problems with Rubber Rollers [Increased Durability with Wear-Resistant EPDM]](https://image.mono.ipros.com/public/default/object/noimage_l.gif?w=280&h=280)

![Solving Problems with Rubber Rollers [Stabilization during Adhesion of Rubber and Shaft]](https://image.mono.ipros.com/public/product/image/dce/2000693433/IPROS84379893903726383893.jpeg?w=280&h=280)

![Solving Your Rubber Roller Problems [Are You Struggling with Replacement Frequency?]](https://image.mono.ipros.com/public/product/image/0be/2000728674/IPROS63705606430156608124.jpeg?w=280&h=280)

![152mm high load-bearing mecanum wheel PU roller [cart/tire]](https://image.mono.ipros.com/public/product/image/dc3/2000441637/IPROS76047602683236156826.jpeg?w=280&h=280)