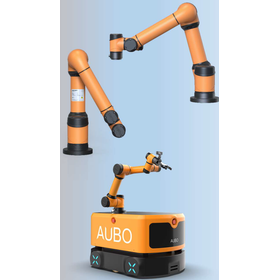

Achieving labor-saving and efficiency through the on-site implementation of collaborative robots, AGVs, and AMRs. Supporting from system proposals to design, assembly, and startup.

Our company handles a variety of products that assist in factory automation, such as electric wires, connectors, and control devices, and we also propose the introduction of robotic systems.

We select robotic devices and safety equipment tailored to the applications and sites from various manufacturers. We provide one-stop support from system proposal to design, assembly, and startup.

★ Currently, we are offering materials that clearly introduce the benefits of "AGV/AMR" and "collaborative robots" used in automation.

【Delivery Achievements】

Pump Manufacturer: Introduced collaborative robots and dedicated carts for machine tending of Hoff plates.

Automotive Parts Manufacturer: Introduced multi-joint robots for automatic lathe devices.

Packaging Equipment Manufacturer: Introduced parallel link robots for bottle alignment devices.

Cable Manufacturing Company: Introduced multi-joint robots for automatic palletizing of winding.

Glass Manufacturing Company: Introduced AMR for automatic transportation between facilities.

*The materials can be viewed immediately via "PDF Download." Please feel free to contact us.

![[Data Presentation] Collaborative Robots with SBC | Realizing AGV/AMR](https://image.mono.ipros.com/public/product/image/16a/2000684875/IPROS57897148198789993905.jpeg?w=280&h=280)

![[Rainbow Robotics] 協働ロボット](https://image.mono.ipros.com/public/product/image/19d/2001200658/IPROS12318608114551279059.png?w=280&h=280)

![[Authorized Dealer] DOBOT Corporation Collaborative Robot CR Series](https://image.mono.ipros.com/public/product/image/6c9/2000737449/IPROS00686246556645838931.png?w=280&h=280)

![[Information] A Thorough Explanation of Two Key Points to Implement Before Introducing Collaborative Robots](https://image.mono.ipros.com/public/product/image/24a/2001486638/IPROS2198454814995025594.jpg?w=280&h=280)