1~45 item / All 49 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry Form1~45 item / All 49 items

Filter by category

The "IUG0101" is a machine that enhances grinding power in the processing of hard and brittle materials by amplifying ultrasonic vibrations and transmitting them to the grinding wheel. *For more details, please contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IMT Series" is a space-saving gantry machining center where the gantry spindle moves while the table remains fixed, unlike conventional gantry machining centers. It is ideal for machining various large materials (milling, drilling, tapping). *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IMT Series" is a space-saving gantry machining center where the gantry spindle moves while the table remains fixed, unlike conventional gantry machining centers. It is ideal for cutting various large materials (milling, drilling, tapping). *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IG-SR102" is a high-reciprocal precision grinding machine specialized for efficiently processing small parts, unlike general grinding machines. It features a compact design that fits within a 1 square meter area. It excels at handling small parts made of difficult-to-machine materials such as carbide and ceramics. *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IV-Line Series" is a dedicated machine for V-groove processing of sheet metal before bending. We respond to changes in size and specifications through custom orders and modifications. 【Features of the IV-Line Series】 ■ High rigidity specifications utilizing know-how from machine tool manufacturing with upper and lower drive sliding guide surfaces ■ High-precision positioning of fixed-length devices through twin drive control ■ Front cover structure designed with safety in mind during processing ■ Easy operation with FANUC control system (touch panel) and dedicated software ■ Customizations such as adding a comb blade for chip removal or changing the stroke are very welcome *For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length machining center is a machining center specialized for long materials (2m to 6m) that performs cutting processes (milling, drilling, tapping). The "ILS series" features a tool magazine built into the column, allowing tool changes at any position on the left or right, making it a high-rigidity machine suitable for long-length metal processing. *BT40 models are also available. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length machining center is a machining center specialized for long materials (2m to 6m) that performs cutting processes (milling, drilling, tapping). The "ILS Series" features a tool magazine built into the column, allowing tool changes at any position on the left or right, making it a high-rigidity machine suitable for long-length metal processing. *BT40 models are also available. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length machining center is a machining center specialized in processing long materials (2m to 6m) through cutting operations (milling, drilling, tapping). The "ILS Series" features a tool magazine built into the column, making it a high-rigidity machine suitable for long-length metal processing, with tool changes possible at any position on the left or right. *BT40 models are also available. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length NC machining machine is a type of machining center specialized for processing long materials (2m to 6m) through cutting operations (milling, drilling, tapping). The "ILM Series" features a tool magazine built into the column, making it a high-rigidity machine suitable for long material processing with tool changes possible at any position on the left or right. ■ Features of the "ILM Series type D" - Added forced lubrication oil specifications and dust-proof specifications for each moving axis to accommodate processing of materials such as FRP and CFRP, in addition to aluminum and iron. - A head designed to consider oil recovery prevents oil from adhering to the material. - The vertical movement of the spindle has been increased from 300mm to 400mm. - The maximum spindle speed has been increased from 8000 min-1 to 10000 min-1. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length machining center is a machining center specialized for long materials (2m to 6m) that performs cutting processes (milling, drilling, tapping). The "ILM Series" is a high-rigidity machine suitable for processing long materials, with a tool magazine built into the column, allowing tool changes at any position on the left or right. *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length machining center is a machining center specialized in processing long materials (2m to 6m) through cutting operations (milling, drilling, tapping). The "ILM Series" features a tool magazine built into the column, making it a high-rigidity machine suitable for long material processing, with tool changes possible at any position on the left or right. *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length NC machining machine is a type of machine, similar to a machining center, that specializes in cutting processing (milling, drilling, tapping) for long materials (2m to 6m). The "ILP series" is a long-length NC machining machine that supports rotational processing of round pipes and square pipes. (Rectangular pipes can also be processed.) *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length machining center is a machining center specialized in processing long materials (2m to 6m) through cutting operations (milling, drilling, tapping). The "ILM Series" features a tool magazine integrated into the column, making it a high-rigidity machine suitable for processing long materials with tool changes possible at any position on the left or right. *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IUG0101" is a machine that enhances grinding power in the processing of hard and brittle materials by amplifying ultrasonic vibrations and transmitting them to the grinding wheel. *For more details, please contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

There are 11 types of milling machines categorized by size and type. ■ NC Milling Machine Size 2# (Knee Type) ○ Vertical NV2 ○ Vertical NR2 (※Ram Specification) ○ Horizontal NH2 【Features of NC Milling Machines】 Can switch between three roles (used as NC, used as a simple NC, used as a general-purpose machine). ■ NC Milling Machine Size 1# (Bed Type) ○ Vertical IB-1V ■ General-purpose Milling Machine Size 2# (Knee Type) ○ Vertical 2VB ○ Vertical 2RC (※Ram Specification) ○ Horizontal 2HB ■ General-purpose Milling Machine Size 1# (Knee Type) ○ Vertical NKS-1 ○ Vertical NK-1R (※Ram Specification) ○ Horizontal NK-1 ○ Horizontal NK-1F (※Automatic Cycle Specification) *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

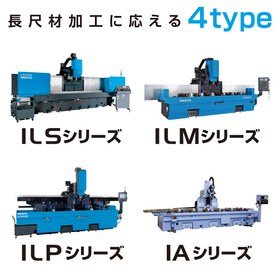

A long-length machining center is a machining center specialized for long materials (2m to 6m) that performs cutting processes (milling, drilling, tapping). There are four types available, so you can choose according to your application. ■ ILM Series (Spindle: BT40) This is a high-rigidity machine particularly suitable for processing aluminum long materials, with a tool magazine built into the column and the ability to change tools at any position on the left or right. ■ ILS Series (Spindle: BT50) This is a high-rigidity machine suitable for processing long iron materials, with a tool magazine built into the column and the ability to change tools at any position on the left or right. *There is also a BT40 model available. ■ ILP Series (Spindle: BT30) This is a long-length NC machining machine that supports the rotational processing of aluminum round pipes and square pipes. (Rectangular pipes can also be processed.) ■ IA Series (Spindle: BT30) This is a machine suitable for aluminum long processing, featuring an efficient tool change capability with a 6-axis turret head. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length machining center is a machining center specialized for long materials (2m to 6m) that performs cutting processes (milling, drilling, tapping). The "ILM Series" is a high-rigidity machine suitable for processing long materials, featuring a tool magazine built into the column, allowing tool changes at any position on the left or right. *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length NC machining machine is a type of machine, similar to a machining center, that specializes in processing long materials (2m to 6m) through cutting operations (milling, drilling, and tapping). The "ILM Series" is a high-rigidity machine suitable for long material processing, featuring a tool magazine built into the column, allowing tool changes at any position on the left or right. *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length machining center is a machining center specialized in processing long materials (2m to 6m) through cutting operations (milling, drilling, tapping). The "ILS Series" features a tool magazine integrated into the column, making it a high-rigidity machine suitable for long-length metal processing, with tool changes possible at any position on the left or right. *BT40 models are also available. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length NC machining machine is a type of machining center specialized for processing long materials (2m to 6m) through cutting operations (milling, drilling, and tapping). The "ILM Series" features a tool magazine built into the column, making it a high-rigidity machine suitable for long material processing with tool changes possible at any position on the left or right. ■ Features of the "ILM Series type D" - Additional forced lubrication oil specifications and dust-proof specifications for each moving axis to accommodate processing of materials other than aluminum and iron, such as FRP and CFRP. - A head designed to prevent oil adhesion to materials by considering oil recovery. - The vertical movement of the spindle increased from 300mm to 400mm. - The maximum spindle speed increased from 8000 min-1 to 10000 min-1. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length NC machining machine is a type of machine, similar to a machining center, that specializes in cutting long materials (ranging from 2m to 6m) through processes such as milling, drilling, and threading. The "ILP series" is a long-length NC machining machine that supports the rotational processing of round and square pipes. (Rectangular pipes can also be processed.) *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A long-length NC machining machine is a type of machine, similar to a machining center, that specializes in processing long materials (2m to 6m) through cutting operations (milling, drilling, and tapping). The "IA Series" is an optimal machine for long aluminum processing, featuring an efficient tool exchange with a 6-axis turret head. For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

An aluminum cutting machine is a device that cuts aluminum profiles (long materials) and aluminum sheets (large sheets) to specified dimensions. The 'IQ (Overcut)/IQU (Undercut) series' cuts aluminum profiles with high precision and efficiency. ■ Features ○ Custom-made cutting machines tailored to customer needs ○ Simply input numerical values on a dedicated screen to cut to specified dimensions and quantities ○ Fully automatic cutting machines, including automatic loading and unloading of workpieces, are also available ■ About Each Series ○ IQ Series The cutter position remains constant, maintaining high cutting accuracy even when material sizes change. ○ IQU Series The cutter moves within a cover, ensuring safety at the work surface. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

An aluminum cutting machine is a machine that cuts aluminum profiles (long materials) and aluminum sheets (large sheets) to specified dimensions. The "IQR (Running Saw) Series" is compatible with various aluminum sheet cutting applications. *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IMT Series" is a space-saving gantry machining center where the gantry spindle moves while the table remains fixed, unlike conventional gantry machining centers. It is ideal for machining various large materials (milling, drilling, tapping). *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have built over 20 years of experience in creating products based on our product lineup as well as fully customized machines from scratch. By listening to our customers' requests and engaging in discussions, we develop concepts together. The machines produced based on these interactions become truly one-of-a-kind custom machines in the world. Since these machines often have a deep understanding of our customers' work, we cannot publicly disclose many of our achievements, but we have compiled some of the projects we have handled into a collection titled "Production Case Studies." ■ Advantages of Special Machine Tools and Dedicated Machines ○ Increased productivity and cost reduction through reduced setup and processing time ○ Improved quality due to machine structures specialized for processing content ★ We are offering a collection of case studies featuring numerous examples of special machine tools and dedicated machines for free! ★ → Please download and view the production case studies.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Iwashita, we specialize in the production of custom-made special machinery and dedicated machines, and an important reason for this is that we carry out all critical parts in-house through integrated production. By adding various units to the base machine, we complete machines equipped with new added value. The NC control for the base machine is compatible with FANUC and Mitsubishi. [Examples of units that can be combined with the base machine] ■ Laser processing unit ■ Ultrasonic unit ■ High-speed spindle Please feel free to consult us about combinations with units other than these. Our experienced staff will consider whether we can accommodate your request. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IV-Line Series" is a dedicated machine for V-grooving of sheet metal before bending. We accommodate changes in size and specifications through custom orders and modifications. 【Features of the IV-Line Series】 ■ High rigidity specification utilizing know-how from machine tool manufacturing with upper and lower drive sliding guide surfaces ■ High-precision positioning of fixed-length devices through twin drive control ■ Front cover structure designed with safety in mind during processing ■ Easy operation with FANUC control system (touch panel) and dedicated software ■ Customizations such as adding a comb blade for chip removal or changing the stroke are highly welcomed *For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IG-SR102" is a high-reciprocal precision grinding machine specifically designed for efficiently processing small parts, unlike conventional grinding machines. It features a compact design that fits within a 1m square area. It excels at handling small components made from difficult-to-machine materials such as carbide and ceramics. *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IG-SR102" is a full-cover model high-precision grinding machine specialized for efficiently processing small parts, unlike general grinding machines. It features a compact design that fits within a 1 square meter area. It excels at handling small parts made from difficult-to-machine materials such as carbide and ceramics. *For more details, please contact us or download the catalog.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "NK-1R" is a compact #1 ram-type vertical milling machine (knee type) that is ideal for mold making, jigs, and small parts processing. It comes standard with digital scales for the X and Y axes. The main specifications include a table size of 1100×270mm, a left-right travel of 600mm, a front-back travel of 270mm, and a vertical travel of 400mm. There are also special specifications available, such as a raising block, additional digital scales (up and down), and an under-chip pan. 【Features】 - Equipped with an automatic feed device for the quill - Equipped with a left-right cutting feed device - Equipped with a left-right rapid feed device - Head tilts left and right up to 45° - Equipped with a cutting oil device *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "NKS-1" is a compact #1 vertical milling machine (knee type) ideal for mold making, jigs, and small parts processing. It comes standard with digital scales on the X and Y axes. The main specifications include a table size of 955×210mm, a left-right travel of 610mm, a front-back travel of 200mm, and a vertical travel of 400mm. There are also special specifications available, such as additional digital scales (vertical) and an under-chip pan. 【Features】 ○ Equipped with an automatic feed device for the quill ○ Equipped with a left-right cutting feed device ○ Equipped with a left-right rapid feed device ○ Head tilts 45° to the left and right ○ Equipped with a cutting oil system *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "NK-1F" is a compact #1 knee-type horizontal milling machine that offers powerful cutting and simple operability. Its main specifications include a table size of 955×210mm, a left-right travel of 400mm, a front-back travel of 200mm, and a vertical travel of 400mm. There are also special specifications available, such as a vertical attachment, digital scales for 2-axis/3-axis, and an under-chip pan. 【Features】 ○ One-axis NC specification for left-right movement ○ Ball screws and servo motors are used for the left-right axis ○ Cutting feed and rapid feed for the left-right axis can be set as desired ○ Programs for the left-right axis can be created on the NC screen ○ Easy setting of left-right axis operations with auto cycle 【Advantages of Down-Cutting】 ○ Since there is no upward thrust on the arbor, it results in a high-precision and clean cutting surface ○ Tool life is improved, and holding fixtures become simpler ○ Cutting speed can be increased For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "NK-1F" is a compact #1 horizontal milling machine (knee type) that offers powerful cutting and simple operability. Its main specifications include a table size of 955×210mm, a left-right travel of 400mm, a front-back travel of 200mm, and a vertical travel of 400mm. There are also special specifications available, such as a vertical attachment, digital scales for 2-axis/3-axis, and an under-chip pan. 【Features】 ○ One-axis NC specification for left-right movement ○ Ball screws and servo motors are used for the left-right axis ○ Cutting feed and rapid feed for the left-right axis can be set arbitrarily ○ Program creation for the left-right axis can be done on the NC screen ○ Easy setting of left-right axis operation with auto cycle *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "NK-1" is a compact #1 horizontal milling machine (knee type) with powerful cutting capabilities and simple operability. Its main specifications include a table size of 955×210mm, a left-right travel of 610mm, a front-back travel of 200mm, and a vertical travel of 400mm. There are also special specifications available, such as a vertical attachment, digital scales for 2-axis/3-axis, and an under-chip pan. 【Features】 ○ Equipped with left-right cutting feed device ○ Equipped with left-right rapid feed device ○ Equipped with cutting oil device ○ Suitable for heavy cutting *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "2VB" is a vertical, general-purpose milling machine of the second class (Knee type). ■Features ○ The three axes of left-right, front-back, and up-down feed use ball screws with extremely low backlash. ○ The front-back ball screws are positioned at the center of the sliding surface, enabling high-precision machining without wandering. ○ The automatic feed for left-right and front-back uses AC servo motors for stepless speed variation. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "2HB" is a horizontal, general-purpose milling machine of Class 2 (knee type). ■Features ○ The three axes of left-right, front-back, and up-down feed use ball screws with extremely low backlash. ○ The front-back ball screws are positioned at the center of the sliding surface, enabling high-precision machining without wavering. ○ The automatic feed for left-right and front-back uses stepless speed variation with AC servo motors. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "2RC" is a knee-type vertical milling machine with a ram design that boasts high cutting capabilities. The three axes of left-right, front-back, and up-down feed utilize ball screws with extremely low backlash, allowing for smooth feeding and precise positioning. The main specifications include a table size of 1100×280mm, a left-right travel of 700mm, a front-back travel of 300mm, and a vertical travel of 400mm. 【Features】 - Digital display adopted for accurate reading of quill movement - The spindle integrated into the quill allows for automatic vertical feeding with three-speed transmission - To achieve more precise positioning, a fine feed mechanism is standard on the left-right and front-back feed handles - To improve machining efficiency, left-right and front-back travel distances are read via a digital scale and displayed on a counter - Standard features include an under-chip pan and rear fence to minimize floor contamination from falling chips and cutting oil during machining *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "IB-1V" is a bed-type NC milling machine where the workpiece is fixed to the table and the head moves, making it easy to attach and detach the workpiece and providing excellent accessibility. The guidance processing menu on the operation panel allows for operations such as circular machining and angled cutting, which were not possible with conventional general-purpose milling machines, to be performed with just one manual round handle. Additionally, two processing methods can be selected: manual handle and automatic feed, significantly improving efficiency compared to traditional general-purpose milling machines. 【Features】 ○ Operation guidance function to support machining ○ Table-fixed design for good accessibility ○ User-friendly teaching function (special specification) *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "NH2" is a #2 NC horizontal milling machine (knee type) that allows switching between NC milling, simple NC, and general-purpose milling with the push of a button. Its main specifications include a table size of 1100×280mm, a left-right travel of 700mm, a front-back travel of 300mm, and a vertical travel of 400mm. 【Features】 - As a general-purpose machine, it offers the same operability as conventional general-purpose machines with mechanical handles for left-right and front-back movements. - As a simple NC machine, it features an operation guidance function that allows R processing and angled processing with just one handle. - As an NC milling machine, in addition to the conventional programming functions, the operation guidance function enables easy programming while viewing illustrations. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "NR2" is a type 2 NC ram vertical milling machine (knee type) that allows switching between NC milling, simple NC, and general-purpose milling with the push of a button. Its main specifications include a table size of 1100×280mm, a left-right travel of 700mm, a front-back travel of 300mm, and a vertical travel of 400mm. 【Features】 ○ As a general-purpose machine, it offers the same operability as conventional general-purpose machines with mechanical handles for left-right and front-back movements. ○ As a simple NC machine, it allows for R processing and angled processing with just one handle using the operation guidance function. ○ As an NC milling machine, in addition to conventional programming functions, it enables easy program creation while viewing images through the operation guidance function. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "NV2" is a #2 NC vertical milling machine (knee type) that allows switching between NC milling machine, simple NC, and general-purpose milling machine with just one switch. Its main specifications include a table size of 1100×280mm, a left-right travel of 700mm, a front-back travel of 300mm, and a vertical travel of 400mm. The head and column are integrated. 【Features】 ○ As a general-purpose machine, it offers the same operability as conventional general-purpose machines with mechanical handles for left-right and front-back movements. ○ As a simple NC, it allows R processing and angled processing with just one handle through an operation guidance function. ○ As an NC milling machine, in addition to the conventional programming function, it enables easy program creation by viewing images with the operation guidance function. *For more details, please contact us or download the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Sun Echo Co., Ltd. has introduced the "Long-Length NC Machining ILM Series." We will introduce the purpose and effects of this implementation. At the company's Nakajo factory, there was a need to introduce a machining machine that could produce at least the same quality and speed as the previous equipment, or even better. After the introduction of this product, the movement speed and tool change speed have also increased, leading to a definite improvement in production efficiency and the ability to accommodate increased production. [Case Study] ■ Overview: NC machining of aluminum materials specialized for aircraft interior components ■ Implementation Site: Sun Echo Co., Ltd. ■ Implemented Product: Long-Length NC Machining ILM Series *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the background and reasons behind Mima Shutter Co., Ltd.'s consideration and decision to introduce the "long-length NC processing machine." About 15 years ago, the company began to see a decline in demand for shutters, making entry into other fields essential. They were approached by a furniture manufacturer to produce aluminum materials for furniture, but the level of dimensional accuracy required was completely different from that of shutters, prompting them to consider our products. After introducing our product, they were able to transform their business to produce high-precision, small-batch products in the residential sector. [Case Study] ■ Overview: NC processing of aluminum profiles specialized for furniture materials and residential building materials ■ Client: Mima Shutter Co., Ltd. ■ Introduced Product: Long-length NC processing machine *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will introduce the reasons behind Takabatake Co., Ltd.'s introduction of the "long-length NC processing machine" and its effects. The company primarily manufactured building materials for low-rise buildings, focusing on screen doors, but has begun to pursue originality in building materials for rental properties, leading them to seek methods that do not require molds. After introducing this product, they have been able to utilize the long-length machine not only for small lot responses but also from the prototype stage. Additionally, the speed of being able to start production immediately after creating a program has resulted in a high volume of prototype orders. [Case Study] ■ Overview: Engaged in NC processing of a wide range of aluminum materials, from building materials to non-building materials. ■ Implementation Site: Takabatake Co., Ltd. ■ Implemented Product: Long-length NC processing machine *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration